What effect do vaping and air pollution have on your heart, and how could a light-powered pacemaker improve cardiovascular health?

It seems that every day, scientists are learning more about the factors affecting cardiovascular health and are coming up with novel ways to keep our hearts ticking for longer. Here are three interesting recent developments.

A less painful pacemaker

One of the problems with existing pacemakers is that they are implanted into the heart with one or two points of connection (using screws or hooks). According to University of Arizona researchers, when these devices detect a dangerous irregularity they send an electrical shock through the whole heart to regulate its beat.

These researchers believe their battery-free, light-powered pacemaker could improve the quality of life of heart disease patients through the increased precision of their device.

The way existing pacemakers work can be quite painful for heart disease patients.

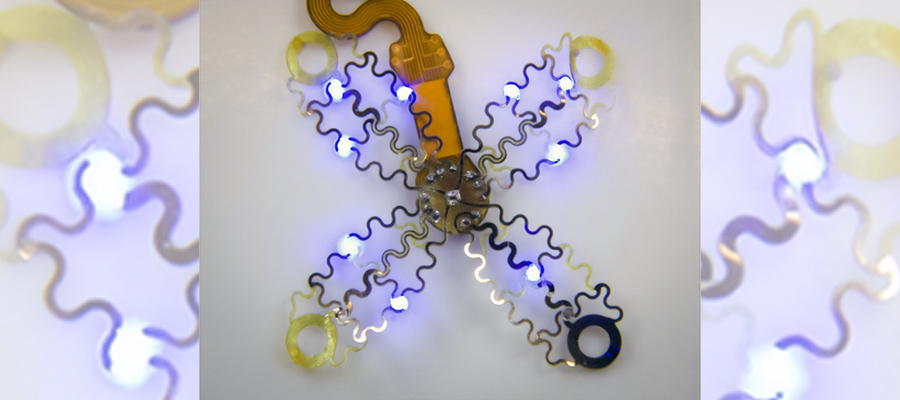

Their pacemaker comprises a petal-like structure made from a thin flexible film (that contains light sources) and a recording electrode. Like the petals of a flower closing up at night, this mesh pacemaker envelops the heart to provide many points of contact.

The device also uses optogenetics – a biological technique to control the activity of cells using light. The researchers say this helps to control the heart far more precisely and bypass pain receptors.

‘Right now, we have to shock the whole heart to do this, [but] these new devices can do much more precise targeting, making defibrillation both more effective and less painful,’ said Igor Efimov, professor of biomedical engineering and medicine at Northwestern University.

‘Current pacemakers record basically a simple threshold, and they will tell you,’ added Philipp Gutruf, lead researcher and biomedical engineering assistant professor. ‘This is going into arrhythmia, now shock, but this device has a computer on board where you can input different algorithms that allow you to pace in a more sophisticated way.’

Another potential benefit is that the light-powered device could negate the need for battery replacement, which is done every five to seven years. That use of light to affect the heart rather than electrical signals could also mean less interference with the device’s recording capabilities and a more complete picture of cardiac episodes.

The device uses light and a technique called optogenetics, which modifies cells that are sensitive to light, then uses light to affect the behavior of those cells. Image by Philipp Gutruff.

>> See how Bright SCIdea winner Cardiatec uses AI to improve heart disease treatment.

The danger of vaping?

We don’t know a lot about the long-term effects of vaping because people simply haven’t been doing it long enough, but a recent study from the University of Wisconsin (UW) suggests that it could be bad for the heart.

Researchers selected a group of people who had used nicotine delivery devices for 4.1 years on average, those who smoked cigarettes for 23 years on average, and non-smokers and compared how their hearts behaved after smoking (the first two groups) and after exercise.

The researchers noticed differences minutes after the first two groups smoked or vaped. ‘Immediately after vaping or smoking, there were worrisome changes in blood pressure, heart rate, heart rate variability and blood vessel tone (constriction),’ said lead study author Matthew Tattersall, an assistant professor of medicine at the University of Wisconsin School of Medicine and Public Health.

The lack of long-term data means we still don’t know the effect of vaping.

Those who vaped also performed worse on the four exercise parameters compared to those who hadn’t used nicotine. Perhaps the most startling finding was the post-exercise response of those who had vaped for just four years compared to those who had smoked tobacco for 23 years.

‘The exercise performance of those who vaped was not significantly different from people who used combustible cigarettes, even though they had vaped for fewer years than the people who smoked and were much younger,’ said Christina Hughey, fellow in cardiovascular medicine at UW Health, the integrated health systems of the University of Wisconsin-Madison.

The influence of lead and air pollution

We know that smoking and passive-smoking are bad for our hearts, but some overlook the effect of other environmental toxins, especially those common to specific geographical regions.

A collaborative study including US and UK researchers has found a divergence in the types of environmental contaminants that contribute to cardiovascular ailments in both countries, aside from the prevalent smoking-related heart disease.

Hopefully, the growth in electric vehicle use will reduce air pollution

The study found that lead-related poisoning is more common in the US, whereas air pollution has a more damaging effect in the UK due mainly to increased population density. The researchers found that 6.5% of cardiovascular deaths were associated with exposure to particulate matter over the past 30 years compared to 5% in the US.

The one plus is that research has found that there has been a steady decline in cardiovascular deaths stemming from lead, smoking, secondhand smoke and air pollution over the past 30 years. Nevertheless, it will be of little comfort to those walking in the trail of exhaust fumes in cities.

‘More research on how environmental risk factors impact our daily lives is needed to help policymakers, public health experts, and communities see the big picture,’ said lead author Anoop Titus, a third-year internal medicine resident at St. Vincent Hospital in Worcester, Massachusetts.

Rarely have science and government been as clearly linked as the initial response to the Covid-19 pandemic, when politicians could be heard claiming they were being ‘led by the science’ as often as they could be seen doing that pointing-with-a-thumb-and-fist thing.

This Thursday, the UK’s Chief Scientific Adviser, Sir Patrick Vallance, will receive the Lister Medal for his leadership during the Covid-19 pandemic, and you can stream it live here, exclusively on SCI’s YouTube channel!

In readiness for Sir Patrick’s lecture, Eoin Redahan looks back at three ways science helped to mitigate the spread of Covid-19.

People will never look at vaccine development the same way. For good or ill, we have realised just how quickly they can now be developed. Similarly, we have realised what can be achieved when the brightest brains come together. These are two of the positive legacies from Covid.

But there are others. Some of the innovations conceived to tackle Covid will now tackle other pathogens. Here are just three of the innovations that emerged…

1. Wastewater warning

As Oscar Wilde once said: ‘We are all in the gutter, but some of us are looking up at the genetic material in stool samples.’

Not many people would find inspiration in wastewater treatment plants when thinking about early warning systems for infectious diseases.

Nevertheless, during the Covid-19 pandemic, researchers at TU Darmstadt in Germany came up with a system that detected Covid infection rates in the general population by analysing their waste – a system so accurate they could detect the presence of Covid among those without recognisable symptoms.

To do this, they examined the genetic material in samples from Frankfurt’s wastewater plants and tested them using the PCR test. They claim that their measurement was so sensitive it could detect fewer than 10 confirmed Covid-19 cases per 100,000 people.

It is inevitable that Covid-19 variants will rise again, but this system could alert us to the need for tighter protective measures as soon as the virus appears in our wastewater.

2. UV air treatment

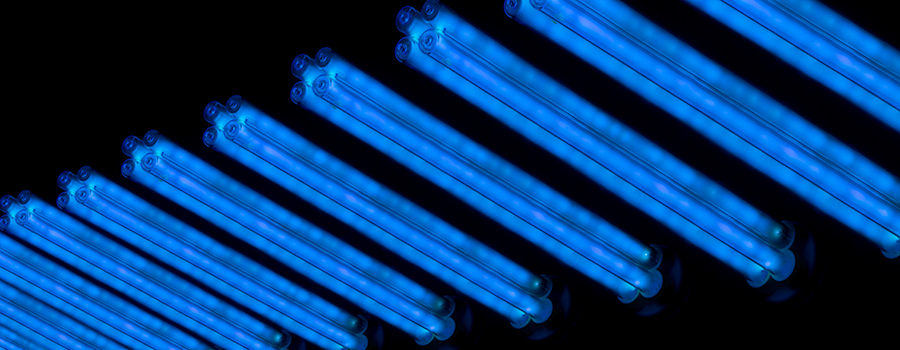

UV light can reportedly reduce indoor airborne microbes by 98%.

Warning systems are important, as are ways to stop the spread of pathogens. To do this, a team from the UK and US shed light on the problem – well, they used ultraviolet light to remove the pathogens.

Using funding from the UK Health Security Agency, Columbia University researchers discovered that far-UVC light from lights installed in the ceiling almost eliminate the indoor transmission of airborne diseases such as Covid-19 and influenza.

The researchers claim it took less than five minutes for their germicidal UV light to reduce indoor airborne microbe levels by more than 98% – and it does the job as long as the light remains switched on.

‘Far-UVC rapidly reduces the amount of active microbes in the indoor air to almost zero, making indoor air essentially as safe as outdoor air,’ said study co-author David Brenner, director of the Center for Radiological Research at Columbia University Vagelos College of Physicians and Surgeons. ‘Using this technology in locations where people gather together indoors could prevent the next potential pandemic.’

3. Biological masks?

‘Physical mask, meet biological mask.’

Many moons ago, it was strange to see a person wearing a mask, even in cities with dubious air quality. Now, they are ubiquitous, and it would appear that mask innovations are everywhere too.

During Covid, researchers from the University of Granada in Spain were aware that wearing masks for a long time could be bad for our health. They devised a near field communication tag for inside our FFP2 masks to monitor CO2 rebreathing. This batteryless, opto-chemical sensor communicates with the wearer’s phone, telling them when CO2 levels are too high.

In the same spirit, researchers in Helsinki, Finland, developed a ‘biological mask’ to counteract Covid-19. The University of Helsinki researchers developed a nasal spray with molecule (TRiSb92) that deactivates the coronavirus spike protein and provides short-term protection against the virus – a sort of biological mask, albeit without those annoying elastics digging into our ears.

‘In animal models, nasally administered TriSb92 offered protection against infection in an exposure situation where all unprotected mice were infected,’ said Anna Mäkelä, postdoctoral researcher and study co-author.

‘Targeting this inhibitory effect of the TriSb92 molecule to a site of the coronavirus spike protein common to all variants of the virus makes it possible to effectively inhibit the ability of all known variants.’

The idea is for this nasal spray to complement vaccines, though during peak Covid paranoia, it might be tricky persuading everyone on the bus that you’re wearing a biological mask.

Covid disrupted scientific progress for many, but as we know, invention shines through in troublesome times. Plenty of innovations such as the ones above will make us better equipped to tackle air borne diseases – alongside the stewardship of leaders like Sir Patrick Vallance.

Watch Sir Patrick Vallance’s talk – Government, Science and Industry: from Covid to Climate – at 18:25 on 24 November

What does clean smell like? What if the fragrance you want to create is that of a sweet-smelling, yet poisonous, flower? In his Scientific Artistry of Fragrances SCITalk, Dr Ellwood led us by the nose.

When Dr Simon Ellwood spoke about creating a fragrance, it sounded like a musical composition or a painting. The flavourist, sitting before a palette of 1,500 fragrance ingredients. Each occupies a different note on the register: the top notes, the middle ones, and the bottom.

To the outsider, this seems impossibly vast and daunting. The Head of Health & Wellbeing Centre of Excellence – Fragrance and Active Beauty Division at Givaudan mentioned that Persil resolved to come up with ‘the smell of clean’ for its detergents in the late 1950s.

But what should clean smell like? Should it be the green, citrusy aromas of this laundry detergent, the smell of mint, or the antiseptic at the hospital?

To make choosing smells slightly less daunting for flavourists and perfumers, they are at least split into odour families such as citrus, floral, green, fruity, spicy, musky, and woody. Some of these ingredients are natural, some are inspired by nature, and others come from petrochemicals and synthetic materials.

The delicious-smelling musk deer.

Deer gland perfume

One of the smells you may have sprayed on your person – one sibling in this odour family – has peculiar origins. The pleasant, powdery smell known as musk was originally extracted from the caudal gland of the male musk deer and from the civet cat.

But as the Colognoisseur website notes, as many as 50 musk deer would have to be killed to obtain one kilogramme of these nodules. Now, killing a load of deer and cats for a few bottles of perfume may not have seemed unethical several centuries ago, but it also wasn’t sustainable or cost-effective. It became clear that a synthetic musk was needed.

When the synthetic musk discovery came in 1888, it was a chance discovery. Albert Bauer had been looking to make explosives when a distinctive smell came instead, along with the scent of opportunity.

>> Read about the science behind your cosmetics

Dior recreated the woodland notes of Lily of the valley.

Do you like the smell of jasmine?

Dr Ellwood’s talk laid bare not only the vastness of everything we smell, but also the ingenuity of those who recreate these odours. In terms of breadth of smell, neroli oil – which is taken from the blossom of a bitter orange – has floral, citrus, fresh, and sweet odours, with notes of mint and caraway. Similarly, and yet dissimilarly, jasmine’s odour families are broken down into sweet, floral, fresh, and fruity, and – jarringly – intensely fecal.

The ingenuity of flavourists is exemplified by lily of the valley. The woodland, bell-shaped flowers are known for their evocative smell, but all parts of the plant are poisonous. Despite this, French company Dior synthetically recreated the lily of the valley smell in its Diorissimo perfume in 1956 using hydroxycitronellal, which is described by the Good Scents Company as having ‘a sweet floral odour with citrus and melon undertones’.

Cyanide smells like almonds, but you might not want to eat it.

Of course, as Dr Ellwood noted, synthetic flavours can only ever get so close to the real thing – an imperfect facsimile. However, the mere fact that chemists have recreated deer musk, lily of the valley, and the prized ambergris from sperm whales to create the fragrances we love is almost as extraordinary as the smells themselves.

‘Fragrance,’ he said, ‘will always be the confluence of the artistry of the perfumer and the chemist.

Register for our free upcoming SCI Talk on the Chemistry behind Beauty & Personal Care Products.

In the second part of our chat with Bright SCIdea finalist Team Eolic Wall, we found out how they prepared for their presentation and judges’ questions, and what’s next for their innovative wind turbine technology.

The road from Eureka moment to finished product is paved with peril. Team Eolic Wall’s idea for small, modular wind turbines that use magnetic levitation to harness more power than existing turbines could bring wind power generation into our very homes. But bringing a groundbreaking product to market is not just about mastering the science. It must make business sense too.

As with the other Bright SCIdea hopefuls, Team Eolic Wall received free training from SCI in the form of online tutorials from experienced professionals including modules on structuring a business, financial modelling, branding, and marketing.

After completing the training, Eolic Wall rose to meet the challenge. The team qualified for the Bright SCIdea final and, with it, the pivotal presentation in front of a live audience and panel of expert judges.

Many of us take it as a given that we speak to people at work in our native tongue. The nuances of communication – the cultural subtleties and oddities of the English language – aren’t a concern. But Team Eolic Wall had to present in their second language.

Pitch perfect?

‘This was not our first international presentation, but it was the first one in a foreign language,’ said Alfredo Calle, Eolic Wall founder, ‘so that's always a little bit intimidating until one gets used to it.’

The key to them nailing the pitch was in the spade-work. Calle and his colleagues rehearsed the speech until they knew it by heart. ‘It’s all about training and preparation,’ he said. ‘The more you rehearse, the more confident you feel when the presentation moment comes.’

Of course, the presentation is predictable but the judges’ questions are less so. Having undergone the rigours of competition, Calle recommends that this year’s entrants prepare by trying to predict the types of questions they will be asked. A cold rehearsal could help with the potentially stunning situation of someone throwing questions at you from strange angles.

That team Eolic Wall presented its technology online made theirs even trickier still, especially given a technical hitch at the beginning. But they had polished the presentation to a smoothness that offset such difficulties and came away as joint winners of the Audience Award.

The only lingering regret for them was that Covid prevented them from coming to London. ‘We wish we could have made it to the final,’ he said. ‘Facing the judges and audience live would have been a tremendously valuable and enriching experience.’

A wind energy democracy

Since the Bright SCIdea final, the Eolic Wall is being built brick by brick. The team has received three grants in recent months including one from ProCiencia, the largest innovation agency of the Peruvian government.

Eolic Wall's wall-mounted wind turbine is designed to power homes and offices in situ.

However, perhaps the most exciting development is the technology itself. ‘We have accomplished a peripherally supported wind turbine that works with magnetic levitation,’ Calle said. ‘That's a huge milestone that makes us believe we are building something big.’

Calle hopes for more investment to develop the technology further. At heart, he believes the Eolic Wall will give regular people the chance to generate affordable wind energy from home.

‘We are working out a solution to democratise wind energy for the sake of this blue rock we call home.’

>> Find out how Team Eolic Wall’s innovative technology in part 1 of this blog.

Do you know how the Academy Awards came to be named the Oscars? What about the story behind the Nobel prize? Behind every award name there is a story, and the Julia Levy Award is no exception.

On the face of it, the Julia Levy Award is about innovation in biomedical applications, but it is the stories of the winners of this SCI Canada award, and Julia Levy herself, that really give it life.

But for a tweak of history, Julia Levy may not have ended up in Canada at all. Born Julia Coppens in Singapore in 1934, she moved to Indonesia in her early childhood. Her father uprooted the family during the Second World War and she left for Vancouver with her mother and sister – her father only joining them after release from a Japanese prisoner-of-war camp.

Julia and her family moved to Vancouver during the Second World War.

After studying bacteriology and immunology at the University of British Columbia (UBC), the young Julia received a PhD in experimental pathology from the University of London. She went on to become a professor at UBC and helped found biopharmaceutical company Quadra Logic Technologies in 1984.

More important than confining her achievements in cold prose, Julia Levy’s work made a profound difference to people’s lives. She developed a groundbreaking photodynamic therapy (PDT) that treated age-related macular degeneration – one of the leading causes of blindness in the elderly. She also created a bladder cancer drug called Photofrin in 1993 and, according to Neil and Susan Bressler, the Visudyne PDT treatment created by Julia and her colleagues was the only proven treatment for certain lesions.

Levy thrived in the business space too, serving as Chief Executive Officer and President of QLT from 1995 to 2001. She has since won a boatload of awards for her achievements, but sometimes the best testimonies come from those who have been inspired by her achievements.

Trailblazing drug discovery systems

For Helen Burt, winner of the 2022 Julia Levy Award and retired Angiotech Professor of Drug Delivery at the University of British Columbia (UBC), Julia has been an inspiration. Here was this UBC professor who jointly founded this big, exciting company – creating medication that improved people’s lives and showing her what was possible.

Helen, an English native, moved to Vancouver in 1976 for her PhD and loved it so much that she stayed. As a professor at UBC, Helen would become a trailblazer in drug delivery systems – a field pioneered earlier by Julia Levy.

‘I was a new assistant professor when she was building Quadra Logic and I would go to talks that she gave,’ Helen said. ‘Essentially, the early technology for QLT was a form of very sophisticated drug delivery [...] It was getting the drug they developed into the eye and irradiating it with light of a specific wavelength.

‘It was very, very targeted. And so, you didn’t get the drug going elsewhere in the body and causing unwanted side effects. So her technology was a form of very advanced drug delivery technology.’

‘For me to win an award that honours Julia Levy and her achievements – I think that's what makes it so special to me.’ – Professor Helen Burt, a former student of Julia Levy, is the Award's most recent recipient.

>> Learn more about SCI Canada.

These talks chimed with the young Helen. If a microbiologist could develop this kind of technology, what was stopping her from developing her own?

She, too, became a pioneer in her field, developing nanoparticle-based drug delivery systems (including those to treat cancer) and a novel drug-eluting coronary stent. According to Professor Laurel Schafer, who put Helen forward for the Julia Levy Award: ‘[Helen] was a trailblazer in new approaches for drug delivery and in research leadership on our campus.’

Importance to Canadian chemistry

Professor Schafer is a hugely accomplished chemist in her own right; and the University of British Columbia chemistry professor’s achievements in catalysis discovery were recognised with the LeSueur Memorial Award at the 2020 Canada Awards.

Julia Levy provided an inspiration to Laurel too, in her case as an exemplar for what Canadian chemists could achieve. ‘The achievements of Julia Levy show that it really can be done right here in Canada, and even right here in British Columbia,’ she said. ‘I grew up in a Canada where I believed that better was elsewhere and our job was to attract better here – a very colonial attitude.

Julia studied at and later became a Professor at the University of British Columbia – the campus is pictured above.

‘I now believe and know that better is right here. Professor Levy’s work showed that world-leading contributions come from UBC and from the laboratories led by women.’

She noted that the Julia Levy Award acknowledges Canadian innovation in health science, whereas Canadian chemistry has historically focused on process chemistry in areas such as mining and petrochemicals.

But Julia Levy’s influence permeates beyond science. ‘Julia is one of those people who has been willing throughout her whole career – even now, well into her eighties – to give back to the community,’ Professor Burt says. ‘She mentors, she coaches, she sits on the boards of startup companies, and she advises.’

‘She’s just got this incredible amount of knowledge… She was the Chief Executive Officer [at QLT], so she learnt all of the aspects: the complex and sophisticated regulations, knowing how to find the right people to conduct clinical trials, and how to do the scale-up. She really is a legend in terms of giving back to the community. And this is not just in British Columbia – it’s Pan-Canadian.’

Pictured above: Julia Levy

For young chemists, the Julia Levy in the Julia Levy Award may just be a name for now, but for those in the Canadian chemical industry and patients all over the world, her influence and her work resonate.

As Professor Helen Burt said: ‘For me to win an award that honours Julia Levy and her achievements – I think that's what makes it so special to me.’

>> For more information on the Canada Awards, go to: https://bit.ly/3VMwNKa

Imagine owning a small wind turbine that generates all of your home’s energy needs. As the clock counts down on entries for for the 2023 Bright SCIdea Challenge, we caught up with Team Eolic Wall, the Audience Winner for the 2022 competition.

Eolic Wall was always a nice fit for Bright SCIdea. The team spotted a problem in our renewable energy mix and came up with a scientific business idea to solve it. They saw that wind energy is generated for the public, but it isn’t generated by the public. This stands in bright contrast to solar power generation.

‘Today, 40% of all installed capacity in solar energy is based on solar panels installed on the rooftops of home and corporate buildings,’ said Alfredo Calle, founder of Eolic Wall. ‘The remaining 60% correspond to solar farms.’

Eolic Wall's wall-mounted wind turbine is designed to power homes and offices in situ.

The wind industry is different. ‘Only 1% of the installed capacity comes from households and businesses,’ he added. ‘That is, 99% of all installed capacity in the world comes from wind farms. That sort of concentration is a problem that hampers the energy transition.’

Calle believes this disparity hampers the move from fossil fuel dependency to clean, renewable energy. For many, micro-generation is key. We need to put power – renewable power – in the hands of the people. His idea is to make wind energy available in the home, just as solar exists on roofs everywhere.

The scale of this task is daunting. It turns out there’s a reason why we don’t all have wind turbines bolted onto our homes. The problem, Calle argues, is that a windmill must be large to be efficient.

He believes the Eolic Wall could change that – that this wall-mounted wind turbine is efficient enough to power our homes and offices.

‘We have created a technology that not only doubles wind speed to harvest more power from the same wind resources, but also has a wind turbine that works with magnetic levitation to almost eliminate any friction.’

From applicant to finalist

So, how did a team based out of the National University of Engineering in Peru and Universidade Estadual Paulista in Brazil end up competing for the £5,000 first prize in the Bright SCIdea final?

Chance. Fortune. Happenstance. Calle and his colleagues came upon Bright SCIdea through a social media post that immediately captured their attention.

‘We thought that the Eolic Wall was ideal for Bright SCIdea because of the huge positive impact that this technology could have,’ he said, ‘and also because it perfectly fit into Bright SCIdea’s thesis of supporting ideas in the intersection of business, innovation and science.’

Applying was simple, although the business plan submission was intimidating at first. However, like all BrightSCIdea applicants they received coaching, and their brainchild found form.

‘The key driver to overcome that challenge was not to miss any training sessions and tutorials,’ Calle said. ‘The good news is that after going through the whole process you feel that everything was worthwhile. No pain, no gain.’

Check out fellow 2022 finalist Klara Hatinova from Team Happy BioPatch in conversation with the Periodic Fable podcast.

Little machines that blend makeup tailored for your skin alone… Technology that details the tiny creatures walking on your face… The cosmetic revolution is coming, and Dr Barbara Brockway told us all about it.

Max Huber burnt his face. The lab experiment left him scarred, and he couldn’t find a way to heal it. So, he turned to the sea. Inspired by the regenerative powers of seaweed, he conducted experiment after experiment – 6,000 in all – until he created his miracle broth in 1965. You might know this moisturiser as Crème de la Mer.

A rocket scientist in the world of cosmetics seems strange, but when you interrogate it, it isn’t strange at all. As Dr Barbara Brockway, a scientific advisor in cosmetics and personal care, explained in our latest SCItalk, cosmetics hang from the many branches of science.

Engineering, computer science, maths, biology, chemistry, statistics, artificial intelligence, and bioinformatics are among the disciplines that create the creams you knead into your face, the sprays that stun your hair in place. They say it takes a village to raise a child, and it takes an army of scientists to formulate all the creams, gels, lotions, body milks, and sprays in your cupboard.

Some say sea kelp can be used to treat everything from diabetes, cardiovascular diseases, and cancer, to repairing your nails and skin.

There is a reason why the chemistry behind these products is so advanced. If you sell bread, it is made to last a week. If you make a moisturising cream, it is formulated to last three years. To make sure it does that, chemists test it at elevated temperatures to speed up the time frame. They conduct vibration tests and freeze-thaw tests to measure its stability.

Dr Brockway likened the process of bringing a product to market to a game of snakes and ladders. If you climb enough ladders, you could take your own miracle brew to market within 10 months.

But expectations are high, and the product must delight the user. Think of the teenager who empties a half a can of Lynx Africa into his armpit, or the perfume that is a dream inhaled. Each smell she likened to a musical composition.

But these formulators are not struggling artists. Perfumers and cosmetic chemists – these bottlers of love and longing and loss – can earn a fortune. Dr Brockway’s quick calculation provided a glimpse of the lucre.

Take 15kg of the bulk cream you mixed on your kitchen table. That same cream could be turned into 1,000 15ml bottles, each sold for £78. So, just 15kg of product could fetch £78,000. So, it’s easy to see why the global beauty market is worth $483 billion (£427 billion), with the UK market alone worth £7.8 billion – more than the furniture industry.

Smart mirror, mirror, on the wall…

It’s unsurprising that an industry of such value and scientific breadth embraces the latest technologies, from those found in our phones to advances in genetics and the omics revolution.

Already, the digital world has left the makeup tester behind. Smart mirrors overlay virtual makeup, recommend products for your complexion, and even detect skin conditions. Small machines that look like coffee-makes blend bespoke makeup. Indeed, Dr Brockway noted that Yves Saint Laurent has created a blender that produces up to 15,000 different shades.

Even blockchain has elbowed into the act. It is being used to make sure that a product’s ingredients aren’t changed in between batches. By showing customers every time-stamped link of the supply chain, companies can prove that their products are organic or ethically sourced. The reason why blockchain is significant here is that, once recorded, the data stored cannot be amended.

At first glance, proving the provenance of materials to customers might seem like a marketing ploy, but this is also being done in response to the increasing fussiness of the consumer.

Collagen is the main component of connective tissue.

Dr Brockway said all brands are now under pressure to incorporate sustainability into their business practices. The younger age group is also looking for more organic, vegan-friendly ingredients, and businesses have had to respond.

For example, microbial fermentation is being used instead of roosters’ coxcombs to create hyaluronic acid. Similarly, Geltor claims to have created the first ever biodesigned vegan human collagen for skincare (HumaColl21®). Such collagen is usually provided by our friends the fish.

These advances are significant, certainly to the life expectancies of roosters and fish, but of such ingredients revolutions are not made. Other forces will shake the industry.

Meditating on omics

Back in the 1970s, scientists thought the microbes that live on our skin were simple, but next-generation DNA technology reveals that thousands of species of bacteria live on our skin (a pleasant thought). Dr Brockway says these microbes tell us about our lifestyles – to the point that they even know if you own a pet.

So, what is the significance of this? Developments in DNA technology and omics (various disciplines in biology including genomics, proteomics, metagenomics, and metabolomics) mean we can now get not just a snapshot, but an entire picture of what’s going on on your face.

‘Thanks to omics we really know what’s now going on with our skin and see what our products are doing,’ Dr Brockway said. ‘We know the target better. We know which collagens, out of the 263, we need to encourage.’

We are learning more and more about how our skin behaves. And those time-honoured potions and lotions espoused by our grandparents – it will make sense soon, not just why they work, but why they work for some and not for others. In cosmetics, we are leaving the era of checkers and entering the age of chess.

This is the first of three cosmetic SCItalks between now and Christmas. Register now for the Scientific artistry of fragrances.

Reading outside his research area and efficient chemistry helped 2022 Perkin Medal winner Dennis Liotta develop groundbreaking drugs.

There has been an explosion of statistics in football, but one of the most influential figures in this revolution, Ramm Mylvaganam, didn’t care for the game. He worked for the confectionary company Mars. He sold chairs. He knew nothing about football.

However, this key figure outlined in Rory Smith’s recent book, Expected Goals: The story of how data conquered football, came into the field of football analysis and changed the game forever – partly because he approached the game with the fresh perspective of the outsider.

So, what do football statistics have to do with a chemist who came up with life-saving medications? Well, Dr Dennis Liotta, who came up with AIDS antivirals that have saved thousands of lives, may not have entered medicinal chemistry as a complete outsider. He was a chemist, after all. However, like Ramm Mylvaganam, his broad breadth of knowledge from different areas gave him a unique perspective on a new field.

Reading at random

Dr Liotta didn’t take the standard path into medicinal chemistry. In fact, he wasn't a diligent chemistry student at first – and that, in an odd way, contributed to his later success.

For the first couple of years at university, he was more interested in his extracurricular activities; but in his third year, he realised he needed to catch up. He worked hard and burnt the midnight oil. He also did something unusual.

‘I did something that’s kind of ridiculous-sounding,’ he said. ‘I had this big fat organic chemistry book, and I would just open it up randomly to some page and read 10 or 12 pages and close it back up. Over time, I ended up covering not only the things I missed, but actually learning about a lot of things that wouldn't have been covered.’

As his career progressed, Dr Liotta realised the importance of not just working harder, but working smarter. On Sundays, he would sit down with a bunch of academic journals to stay abreast of developments. However, as he read them, he discovered other papers – ones outside his research area – that piqued his interest.

Dennis Liotta in one of his lab spaces at Emory. Image by Marcusrpolo.

‘I’d see something intriguing. And so I’d say, that’s interesting, let me read. I started learning about things that I didn’t technically need to know about, because they were outside of my immediate interest. But those things really changed my life. And, ultimately, I think they were the differentiating factor.’

The intellectual stretch

This intellectual curiosity led to more than 100 patents, including a groundbreaking drug in the fight against AIDS that is still used today and a hand in developing an important hepatitis C drug.

‘In science, many times the people who actually make the most significant innovations are the people who come at a problem that’s outside of their field,’ Dr Liotta said. ‘Without realising it, we all get programmed in terms of how we think about problems, what we accept as fact.’

‘But when you come at a problem that’s outside your field… you aren't immersed in it. So, you think about the problems differently. And many times, in thinking about the problems differently, you’ll come up with an alternative solution that people in the field wouldn’t.’

We’ve often heard the stories of Steve Jobs wandering into random classes while at university when he should have been attending his actual course. Apparently, a calligraphy class inspired the font later used in Apple’s products. In other words, early specialism can sometimes hinder creativity.

‘I've looked into people who have made really some amazing contributions, and many times there’s been an intellectual stretch,’ Dr Liotta said. ‘They’ve gone out there and done something that they weren’t really trained to do. You can fall on your face from time to time, but it’s really nice when we're able to make contributions in areas where we don’t really have any formal training.’

Chance favours…

Of course, there’s so much more to creating life-saving drugs than intellectual curiosity and a different way of thinking. Dr Liotta and his colleagues had the technical skill to turn their ideas into something real. He was a skilled chemist who teamed up with an excellent virologist, Raymond Schinazi. The result of this blend of their skills gave them an edge over others developing AIDS therapeutics.

Dr Liotta invented breakthrough HIV drug Emtricitabine.

‘The very first thing we did was we figured out a spectacular way of preparing the compounds – very clean, very efficient,’ he said. ‘And that [meant we could] explore all sorts of different permutations around the series of compounds that others couldn’t easily do, because their methods were so bad for making [them].

‘So, even though we were competing against some very important pharmaceutical companies that had infinitely more money than we had – dozens of really smart people they put on the project – we were able to run circles around them because we had a really efficient methodology and that enabled us to make some compounds.’

The amazing thing is that the very first compound and the third compound the pair came up with led to FDA-approved drugs. It is a fine thing, indeed, when skill and serendipity meet.

‘Chance favours the prepared mind,’ Dr Liotta said, ‘or, as my colleagues say: you work hard to put yourself in a position to get lucky.’

>> Learn more about Dr Liotta’s career path and research from our recent Q&A.

From luminescent polymer nanoparticles that improve rural healthcare to compostable plastic packaging, Dr Zachary Hudson and his research group at the University of British Columbia are developing solutions to pressing issues.

For those of us who live in cities, we take easy access to hospitals for granted, but what about those in remote areas? What if there were an easier way to diagnose diseases and improve healthcare for those in secluded rural areas?

Luminescent dyes used to make fluorescent Pdots.

Well, Dr Zachary Hudson and his group at the University of British Columbia (UBC) in Canada are developing luminescent polymer nanoparticles that could provide portable, low-cost tools for bio-imaging and analysis in rural areas. These nanoparticles are so bright that they can be detected by smartphone, helping clinicians quantify chemical substances of interest such as cancer cells.

Dr Hudson’s work spans other areas too, including working with industry to develop compostable plastics and ongoing research in opto-electronics. His creativity in applied polymer science was recognised recently with the 8th Polymer International-IUPAC award, organised by SCI, the Editorial Board of Polymer International, and IUPAC (International Union of Pure and Applied Chemistry).

We caught up with Zac to ask about these luminous Pdots, compostable plastics, and how it felt to be recognised by his peers.

Dr Zachary Hudson

Tell us about the nanoparticle and remote diagnostic technologies you are developing to boost rural healthcare.

Our group is working with Professor Russ Algar, an analytical chemist at UBC, to develop fluorescent nanoparticles that are bright enough to be detected by a handheld smartphone camera.

The concept is to design nanoparticles that can quantify biological analytes of interest, such as cancer cells or enzymes, and provide a signal that a smartphone can measure. In this way, we hope to create portable, low-cost tools for bioanalysis for use in remote or low-income regions.

Why is the capacity to conduct remote diagnostics so important for those in remote areas?

Coming from Vancouver, I have ready access to sophisticated lab facilities and hospitals that are only a short distance from where I live. This gives me access to some of the world’s most advanced techniques in molecular medicine with relative ease.

For most of the world’s population, however, geography or resources limit their access to these advanced tools that can have a real, positive impact on human health. Expanding access to molecular diagnostic technologies can help more people get the diagnosis they need without a dedicated lab.

How did the ideas for the Pdots come about?

We became interested in Pdots due to Professor Algar’s groundbreaking work using quantum dots for smartphone-based bioanalysis. We learned that by tapping into the versatility of polymer chemistry, we could create polymer nanoparticles, or Pdots, that combined many advanced functions into a single particle.

>> From Covid-19 to the two World Wars, how has adversity shaped innovation? We took a closer look.

How have you worked with other partners to turn these ideas into a reality?

We are currently planning a major initiative with rural health organisations in British Columbia to help move these tools toward practical use. Stay tuned for more info!

You’ve also worked with local industry to reduce the use of single-use plastics. How have you gone about this?

There has been a major push in Canada to reduce the consumption of single-use plastics, and many companies are currently developing new products to respond to this need. Our lab has worked with local industry to formulate and test compostable plastics that can act as substitutes for petroleum-based plastics in consumer packaging.

The Nexe Pod, a fully compostable, plant-based coffee pod created by NEXE Innovations, with Zac as Chief Scientific Officer, received a $1m funding grant from the Canadian government in 2021.

You’ve helped develop compostable materials. How tricky is this from both a material and an environmental perspective?

Compostable plastics are challenging for a few reasons: the demand for them is skyrocketing, so robust supply chains are needed to help companies get away from petroleum feedstocks. The regulatory framework around compostable plastics also varies widely by country, which poses challenges for international commercialisation.

Finally, most machinery for the high-speed manufacturing of plastic packaging is highly optimised for petroleum-based plastics, so new equipment and techniques that are suitable for processing compostable plastics need to be developed alongside the plastics themselves.

>> Do you work in pharmaceutical development? Check out our upcoming events.

What’s next for these innovations, and are you working on anything else interesting?

I've spent most of my career working on light-emitting materials for display technologies and bioimaging, and we’ve recently learned that many of these same materials make useful photocatalysts with applications in the pharmaceutical industry.

We recently partnered with Bristol Myers Squibb to develop all-organic photocatalysts with performance on par with some of the expensive iridium-based catalysts that industry is currently using. I'm looking forward to developing this area further.

What was it like to win the 8th Polymer International-IUPAC award for Creativity in Applied Polymer Science?

It was a great feeling to have our group’s work recognised by the international polymer community. The award lecture at the IUPAC conference also gave us the perfect venue to highlight some of the research directions I’m most excited about in the years ahead.

Have we underestimated the eco-anxiety middle-aged and older people feel? According to a recent survey, younger folks aren’t the only ones frowning at the horizon. Eoin Redahan writes.

When you think of a middle-aged person suffering from exo-anxiety, what do you imagine? Is it a grey-haired woman gazing from a mountain peak with a single, heroic tear staining her cheek? Is it an auld fella rending his garments and shaking his fist at the sun?

I mean, possibly, but the reality is probably less dramatic. It could be the Pakistani householder who wonders if her family home will be swept away in the next flood. It might be the 39-year-old Australian who wonders if his country will be habitable when his young child grows up.

It might be the Maldivian who wonders if his homeland will go the way of Atlantis within 20 years. It was me when someone decided it would be a good idea to have a barbecue in the fields beside my house in the middle of the heatwave – when the grass was as dry as straw and wildfires scorched in south London.

Athanasius Kircher's map of Atlantis, placing it in the middle of the Atlantic Ocean, from Mundus Subterraneus, 1669. Will people pore over maps of the Maldives in the same way?

The presumption by many is that it’s only the young who feel anxious about climate change, for it is they who will inherit the mess. However, according to recent ONS statistics, the middle-aged and the old are almost as worry-weary as young people.

Having analysed a recent ONS Opinions and Lifestyle Survey, straw specialist firm Drinking Straw filtered some of the stats. They reveal that 62% of UK people over the age of 16 worry that rising temperatures will directly affect them by 2030. Of these, 70% of 16-29 year olds were worried about the heat, but 59% of 50-69 year olds were also worried, as were 57% of those aged 70 and over.

In other areas, the differences were even less stark. When it came to anxiety over extreme weather events, 48% of all adults were worried – only slightly less than the 49% of 16 to 29 year olds who did so.

>> How can I make my garden more sustainable? Professor Geoff Dixon shows us how.

Similarly, regarding water supply shortages, 40% of all adults are concerned about them overall, compared to 43% of those aged 16 to 29. Admittedly, young people are more worried than older adults about rising sea levels (45% vs. 31%), but the differences are noticeably narrow in most metrics.

Surprisingly, it turns out the percentage of those who don’t care at all about the merciless heat, parched land, rising sea levels, and freak weather events is fairly consistent across all segments, with the 12% of 16-29 year olds not giving a fig similar to the 14% of indifferent adults.

ONS figures reveal that most people have made climate-friendly changes to their day-to-day lives, whether they grew up in the age of renewables or the age of coal.

Action stations?

Broadly speaking, UK adults are becoming more eco-conscious, if data from the ONS’ Climate change insights, families and households, UK: August 2022 survey are to be believed. The survey has found that 77% of adults have made some, or a lot of changes, to their lifestyles to tackle climate change.

When the remaining 23% were asked why they made no change to their lifestyles, the most common reason given was: the belief that large polluters should make changes before individuals, followed closely by those who felt that individual change wouldn’t make much of a difference.

It’s clear to most of us that the government must help drive change, including on our roads. Despite the UK’s lagging electric vehicle infrastructure, the study revealed that the number of licensed zero emission vehicles, ultra-low emission vehicles, and plug-in vehicles increased by 71% or more last year.

If people knew there were sufficient charging points dotted around their areas – and if they were further incentivised to give up their gas-guzzling vehicles – those numbers would surely increase.

As bleak as the situation is, it is heartening to see our attitudes changing. Now, if you’ll excuse me, I’ve just read a climate-related story that brought a tear to my eye. If anyone wants me, I’ll be weeping in a dark room (passive-cooled, mercifully).

Those with the blood group O reportedly have the lowest likelihood of catching Covid-19, and the new top-up jab should provide relief against sub-variants of the disease.

By now, most of us have been stricken by Covid, but 15% of people in the UK have evaded the virus. According to a testing expert at the London Medical Laboratory, the great escape is down to three factors: blood group, vaccines, and lifestyle.

Having assessed the findings of recent Covid-19 blood type studies, Dr Quinton Fivelman PhD, Chief Scientific Officer at London Medical Laboratory (LML), believes that people with the blood group O are less likely to be infected than those with other blood groups, while those with blood type A are far more likely to contract the virus.

‘There have now been too many studies to ignore which reveal that people have a lower chance of catching the virus, or developing a severe illness, if they have blood group O,’ he said.

Indeed, research from the New England Journal of Medicine had previously found that those with blood type O were 35% less likely to be infected, whereas those with Type A were 45% more vulnerable. A further benefit of type O blood is the reduced risk of heart disease compared to those with type A or B blood.

>> What is the ideal body position to adopt when taking a pill? Wonder no more.

Staged stock images are not thought to increase your chances of contracting Covid-19.

According to the NHS, almost half of the population (48%) has the O blood group; so, clearly, other factors come into play in terms of our susceptibility. Dr Fivelman said: ‘By far the most important factor is the number of antibodies you carry, from inoculations and previous infections, together with your level of overall health and fitness.’

Tackling the sub-variants

So, those who are more careful about visiting crowded places, who eat well, and are fortunate enough not to have an underlying illness have better chances of avoiding Covid-19. According to LML, having been vaccinated also helps, though these benefits have slowly worn off. That is why the new top-up jab with the Omicron variant could provide some relief for those who take it.

‘The new Omicron jab has come none-too-soon, so many people are now suffering repeated Covid infections,’ he added. ‘That’s because the new Omicron BA.4 and BA.5 sub-variants do not produce as high an immune response as the previous strains, so re-infection is more likely to occur.

‘Higher levels of antibodies are important to neutralise the virus, stopping infection and limiting people transmitting the virus to others.’

>> Which herbs could boost your wellbeing? Dr Vivien Rolfe tells us more.

What is the best posture to adopt when taking a pill, and why does it help your body to absorb the medicine quicker?

Was Mary Poppins wrong? A spoonful of sugar may help the medicine go down, but does it do so in the most delightful way? Not according to Johns Hopkins University researchers in the US.

They say the body posture you adopt when taking a pill affects how quickly your body absorbs the medicine by up to an hour. It’s all down to the positioning of the stomach relative to where the pill enters it.

The team identified this after creating StomachSim – a model that simulates drug dissolution mechanics in the stomach. The model works by blending physics and biomechanics to mimic what’s going on when our stomachs digest medicine and food.

Standing up, on your back, or by your side?

Looks like we’ve got a pro here.

Without further ado, here are the four contenders for taking the pill: standing up, lying down on your right side, lying down on your left side, and swallowing the pill on your back.

>> What’s next in wearables? We looked at a few Bright SCIdeas.

According to the researchers, if you take a pill while lying on your left side, it could take more than 100 minutes for the medicine to dissolve. Lying on your back is next in third, the narrowest of whiskers behind swallowing a pill standing up. This time-honoured method takes about 23 minutes to take effect.

However, by far the most effective method (and, therefore, the most delightful way) is lying on your right side, with dissolution taking a mere 10 minutes. The reason is that it sends pills into the deepest part of the stomach, making it 2.3 times faster to dissolve than the upright posture you’re probably taking to swallow your multi-vits.

Your posture is key in ensuring your body absorbs medicine quickly. Image: Khamar Hopkins/John Hopkins University.

‘We were very surprised that posture had such an immense effect on the dissolution rate of a pill,’ said senior author Rajat Mittal, a Johns Hopkins engineer. ‘I never thought about whether I was doing it right or wrong but now I’ll definitely think about it every time I take a pill.’

Next week, we will investigate more of the medical approaches espoused by much-loved fictional characters, starting with George’s Marvellous Medicine, before moving onto the witches in Macbeth. No one is safe.

In the meantime, you can read the researchers’ work in Physics of Fluids.

The Commonwealth Games has landed in Birmingham. Before the Games began, viewers were treated to an extraordinary opening ceremony (featuring a giant mechanical bull) and its artistic director, Iqbal Khan, was lauded for his ingenuity.

But such ingenuity shouldn’t surprise any of us, for Birmingham has long been a place of outsized invention. For more than 300 years, the inhabitants of this industrial powerhouse have churned out invention after invention; and its great pragmatists have turned patents into products.

Chemistry, too, owes a debt to the UK’s second city. Whether it’s the first synthesis of vitamin C, the invention of human-made plastic, adventures in mass spectrometry, or electroplated gold and silver trinkets, Birmingham has left a lasting legacy.

Here are five chemists whose innovations may have made an appearance in your life.

Alexander Parkes – man of plastic

Plaque commemorating Alexander Parkes in Birmingham, England. Image by Oosoom

Look around you. Look at the computer screen, the mouse button you click, and the wire casings everywhere. Someone started it all. That man was Alexander Parkes, inventor of the first human-made plastic.

The son of a brass lock manufacturer from Suffolk Street, Birmingham, Parkes created 66 patents in his lifetime including a process for electroplating delicate works of art. However, none were as influential as the 1856 patent for Parkesine – the world’s first thermoplastic.

Parkes’ celluloid was based on nitrocellulose that had been treated by different solvents. In 1866, he set up the Parkesine Company at Hackney Wick, London, but it floundered due to high cost and quality issues. The spoils of his genius would be enjoyed by the rest of us instead.

Sir Norman Haworth – the vitamin seer

Sir Norman Haworth

Sir Norman Haworth may have been born in Chorley, Lancashire, but his finest work arguably came after he became Director of the Department of Chemistry in the University of Birmingham in 1925. Haworth is famous for his groundbreaking carbohydrate investigations and for being the first to synthesise vitamin C.

By 1928, Haworth had confirmed the structures of maltose, cellobiose, lactose, and the glucoside ring structure of normal sugars, among other structures. Apparently, his method for determining the chain length in methylated polysaccharides also helped confirm the basic features of starch, cellulose, and glycogen molecules.

However, Haworth is most famous for determining the structure of vitamin C and for becoming the first to synthesise it in 1932. The synthesis of what he called ascorbic acid made the commercial production of vitamin C far cheaper – the benefits of which have been felt by millions of us.

For his achievements in carbohydrates and vitamin C, Haworth received the Nobel Prize for Chemistry in 1937 (shared with Paul Karrer). He was the first British organic chemist from the UK to receive this honour. Haworth even had a link to SCI, having been a pupil of William Henry Perkin Junior in the University of Manchester’s Chemistry Department.

Francis William Aston – adventures in mass spectrometry

Blue plaque for Francis William Aston. Image from Tony Hisgett

Another Nobel Prize-winning chemist from Birmingham is Francis William Aston. The Harborne native won the 1922 prize for discovering isotopes in many non-radioactive elements (using his mass spectrograph) and for enunciating the whole number rule.

For a time, academia almost lost Aston, as he spent three years working as a chemist for a brewery. Thankfully, he returned to academic life and obtained concrete evidence for the existence of two isotopes of the inert gas neon before the first World War.

After working for the Royal Aircraft Establishment during the Great War (1914-18), he resumed his studies. The invention of the mass spectrograph proved pivotal to his discoveries thereafter. Using this apparatus, he identified 212 naturally occurring isotopes.

George Elkington and John Wright – all that glitters

George Elkington patented the electroplating process developed by John Wright. Image from Spudgun67

It isn’t surprising that George Elkington should become an SCI favourite, as he blended both scientific ingenuity with business. The son of a spectacle manufacturer patented the first commercial electroplating process invented by Brummie surgeon John Wright in 1840.

Wright discovered that a solution of silver in potassium cyanide was useful for electroplating metals. Elkington and his cousin Henry purchased and patented Wright’s process before using it to improve gold and silver plating.

The Elkingtons opened an electroplating works in the city’s now famous Jewellery Quarter where they electroplated cutlery and jewellery. And they didn’t do too badly out of it. By 1880, the company employed 1,000 people in seven factories.

Alfred Bird – winging it

1906 advertisement for Birds Custard powder. Image from janwillemsen

In 1837, Alfred Bird was in a pickle. He wanted to serve his dinner party guests custard, but his wife was allergic to eggs and yeast, and egg was the main thickening agent of this delicious gloop.

Instead of serving something else, the chemist shop owner invented his own egg-free custard by substituting cornflour for eggs. His guests found it delicious and Bird’s Custard was born.

Not content with this innovation, Bird is also credited with being the father of modern baking powder. Once again, his wife’s allergies were said to be the inspiration, as he wanted to create a yeast-free bread for her. In bread and custard, true love always finds a way.

Paulina Quintanilla has developed a clever way to maximise the froth flotation technology used to extract more valuable minerals from rocks. The SCI Scholar and Poster Competition winner chatted to us about her process and how it could make mineral processing more efficient.

How would you describe your froth flotation technology in simple terms?

Froth flotation is the most widely used technology to separate valuable mineral particles from waste rock. The process is carried out in stirred tanks in which chemical reagents and air are added. Some of these reagents, called collectors, make the valuable mineral particles hydrophobic, which means that they repel water.

Consequently, the valuable mineral particles attach to the air bubbles, covering them and generating bubble-particle aggregates. The bubble-particle aggregates rise to the top of the tank, forming a froth that overflows as a mineral-rich concentrate, while the waste rock leaves from the bottom of the tank as tailings.

Froth flotation is also relevant in several other industrial applications, such as water treatment and paper de-inking.

Schematic of the froth flotation process. Image by @AMPRG_Imperial.

How would you describe your froth flotation technology in simple terms?

This research focuses on optimising the froth flotation process using a control strategy called model predictive control. To this end, mathematical models were developed to represent the phenomena inside a flotation tank. These models are then used to ‘predict the future’ so that decisions can be taken now (we can control the process) to improve the froth flotation performance.

Model predictive control is a powerful optimisation strategy that has been widely used in other processes, including in the petrochemical industry, but it is still very new in the mineral processing industry.

One of the main advantages of this research is that the models are physics-based. This means that they were developed from the fundamental physics of the process rather than from data, which makes them useful under any operating conditions, for any flotation tank size. This is particularly interesting for application in the large flotation tanks used on an industrial scale.

How could this work benefit industry and make processing more efficient?

Building clean technologies for the transition to 100% green energy is creating a massive demand for a range of minerals. For example, copper mines would have to ramp up production considerably to satisfy the extra 7% predicted demand. Meeting that demand, however, is becoming more and more challenging as ores are becoming lower grade, deeper, and more complex.

This implies that there is an urgent need to optimise current processes to extract the necessary minerals and metals more sustainably and efficiently. As froth flotation is a large-scale process, even small improvements in the separation efficiency would translate into important increments in production.

Overflowing froth seen from the top of an industrial-scale tank. Image by @AMPRG_Imperial.What is the potential of this work in terms of copper recovery?

We demonstrated that improvements of between 8 to 22% in metal recovery were achieved by implementing a model predictive control strategy at the laboratory scale, revealing an untapped potential for implementation at an industrial scale. This research could serve as a promising next step for the mining industry to meet future metal and mineral demands by extracting more metal for the same amount of resources, such as water, energy, and chemicals.

>> Interested to find out more about SCI Scholarships?

Your flotation tanks are actually based in Chile. How do you operate them remotely?

I am currently implementing an online model predictive control strategy in a laboratory-scale flotation bank in Chile. I monitor and control this experimental rig from home, in the UK.

The experimental rig was automated in such a way that all the instruments (e.g. air flow meters, controllers, pumps, etc.) are connected to a module called ‘Programmable Logic Controller’. This module is then connected to a workstation computer, which I access from my laptop in the UK.

The Programmable Logic Controller allows me to obtain measurements in real-time and control the system. In this case, the measurements are used to update the mathematical models, while the system is controlled by changing the ‘revolutions per minute’ of the pumps (to change the pulp levels) and/or moving the air valves (to change the airflow rates).

Experimental campaign in 2018 – aerial view of a 300m³ froth flotation tank. Image by @AMPRG_Imperial.

Could this process be used to extract other materials? If so, which ones?

While froth flotation is widely used to separate sulphide minerals of copper, it is also used to separate other sulphides, such as those containing lead, zinc, and molybdenum.

You won an SCI Scholarship. How did you use the funds you received to develop your research?

I used the generous SCI scholarship to partially fund a two-month visit to the laboratory in Chile. I set up new connections for remote control by installing new instrumentation to make it even more automated, and I carried out preliminary online control experiments. Since then, all the control experiments have been carried out from my laptop at home.

I also used the scholarship to fund my participation in several conferences, including one in person in Athens, Greece, in 2021. I have participated in Scholar Days in 2020 and 2021, in which I presented advances in my PhD research to a wide audience. This year, I presented my PhD research results at SCI headquarters for the first time and participated in the Poster Showcase, where I won first place.

Paulina presenting at the SCI Scholars' Showcase in July 2022. Image: SCI/Andrew Lunn

What are your future plans for this innovative technology (and other potential research)?

I plan to keep up the momentum of researching froth flotation optimisation, as I believe that there is still a long way to go for improvement, particularly at an industrial scale. Model predictive control has not been widely explored within the mineral processing industry despite the fact that it has shown great potential. There is still a gap between academia and industry that should be bridged, sooner rather than later, to improve the performance of the process.

Apart from the model predictive control strategy using physics-based models (including the one I have investigated during my PhD research), many other control strategies show great potential to be tested and implemented at an industrial scale.

This is particularly applicable in mineral processing plants, as most of them collect a huge amount of data that could serve as valuable inputs for further improvement and optimisation, using novel engineering tools such as artificial intelligence and digital twins.

Paulina is part of the Advanced Mineral Processing Research Group at Imperial College London, whose research includes fluid dynamics of flotation tanks and multi-criteria decision-making for sustainable mining and mineral processing.

A range of greenhouse gas removal technologies may be necessary if we’re to reach Net Zero by 2050. In the second of our two-part geoengineering feature, Eoin Redahan looks to the sea, the sun, and mineral weathering, and at the ethical concerns such technologies raise. Missed Part One? Find it here.

‘Water, water, everywhere, nor any drop to drink.’

These famous words from Samuel Taylor Coleridge’s Rime of the Ancient Mariner aren’t the only famous part of his epic poem. The term albatross around one’s neck comes from it too.

After shooting a friendly albatross at sea, the poem’s narrator was forced by the ship’s crew to wear the dead creature around his neck – and grievous luck was to follow. Well, our blue planet has an albatross around its neck in the form of climate change.

Perhaps the solution to it lies all around us – water, water, everywhere…

An ocean of potential

In theory, we can use our oceans to pull CO2 from the air on an enormous scale. All it may take is clever intervention – potentially ruinous, albatross-shooting intervention.

Nevertheless, the World Economic Forum lays out the tantalising potential. ‘Ocean-based CO2 removal can help us achieve “net negative emissions” as the seas hold 50 times more carbon than the atmosphere,’ it says.

‘The ocean [is] a sink for nearly one third of anthropogenic carbon emissions and more than 90% of the resulting heat… If we are going to manage atmospheric CO2 levels to our advantage, we will need to leverage the ocean’s existing ability to govern the global carbon cycle.’

Frontier has targeted the development of scalable sources of alkalinity. The reasoning behind it is that with CO2 being an acidic molecule, rising CO2 concentrations could be neutralised through alkalinity. It has mentioned using mine tailings to remove up to 0.5 gigatonnes of CO2 from the air each year; but the major caveat here is that it needs to be done safely.

Planetary Technologies has ventured into this space armed, essentially, with a bicarbonate of baking soda that could draw in CO2 and sequester it for millenia.

The company explains its process: ‘We start by carefully extracting key parts of the mine tailings including recovering battery metals (like nickel and cobalt) and silica (sand) and then take the remaining purified metal salt solution into a special electrolyser. There, using clean, renewable electricity, the salt and water are split to make hydrogen (a clean, emissions-free fuel), and a pure alkaline hydroxide.

‘It’s from this point that we transport the bulk alkaline materials to our ocean outfalls site where the alkalinity is introduced to the surface ocean that then draws in CO2, sequestering it as already abundant bicarbonate and carbonate ions in seawater.’

So, by decreasing the acidity of the ocean, it would have a greater capacity to absorb CO2 from the air. The key, however, is to reduce this to a viable price point.

>> Want to read about iron fertilisation in our oceans? Rhiannon Garth Jones took a closer look here.

Mineral weathering, methane capture, and more

Mineral weathering is another contender in the CO2 removal mix. One technology that recently received $2.4m in funding is Seattle-based Lithos’ enhanced weathering process – a mineral weathering process that could capture CO2 at a gigatonne scale. According to Frontier, Lithos spreads basalt on croplands to increase dissolved organic carbon, before eventually being stored as ocean bicarbonate. The idea is to maximise CO2 removal while bolstering crop growth.

Closer to home, SAC Consulting in Edinburgh will receive £2.9m to capture the methane produced by cattle and cut emissions from the livestock farming sector; Synthetic Biology in San Francisco has received an R&D grant to synthesise a polymer within algae that is capable of sequestering atmospheric CO2 at a large scale; and Charm Industrial is converting plants into a carbon-rich liquid that is pumped underground.

To do the latter, Charm grows cellulosic biomass that captures CO2 from the atmosphere. It is then harvested, ground, and heated, before being turned into a bio-oil that is pumped underground.

Even the concrete beneath our feet could be used as a carbon sink. CarbonCure is injecting CO2 into its concrete mixes, which it says is not only comparable in cost to traditional concrete, but stronger.

And then, we have solar engineering – arguably the first technology that comes into many of our minds when we think of carbon removal. All sorts of geoengineering technologies exist in this sphere including cirrus cloud thinning, stratospheric aerosol scattering, and marine cloud brightening.

Ethical issues?

Interestingly, Harvard’s Solar Geoengineering Research Programme referred to geoengineering as ‘a set of emerging technologies that could manipulate the environment and partially offset some of the impacts of climate change’.

Therein lies the problem for many. What are the consequences of ‘manipulating the environment’, especially if these technologies fall into unscrupulous hands?

In her excellent blog for SCI on geoengineering, Rhiannon Garth-Jones referred to the Haida Corporation Salmon trial. In this trial, 120 tonnes of iron compound were deposited in the migration routes of pink and sockeye salmon in the Pacific Ocean, which resulted in a several-month-long phytoplankton bloom.

It was seen by many as a success. The phytoplankton fed fish and increased biodiversity and the iron sequestered carbon; but Environment Canada believed the corporation violated national environmental laws by depositing iron without a permit.

History teaches us that profit vs. planet tussles don’t always go the way we would like, and the consequences of these technologies going into the wrong hands could be catastrophic.

On 29 June, The World Economic Forum called for a code of conduct for ocean-based CO2 removal; and the American Geophysical Union, a group of climate and planetary scientists, is leading the way in developing an ethical framework for climate intervention engagement.

We’re all feeling the effects of climate change. As I write this piece on 19 July, it is 39°C here in Greenford, London. 39°C in London! The earth is cracking, planes are circling (because the runways are melting), and grass fires are blazing in Croydon.

On days like today, it feels like we need all the innovation we can get.

From the Black Death to the Covid-19 pandemic, great adversity has also led to great advances. So, which inventions have emerged from times of hardship? Eoin Redahan finds out.

‘World events shape innovations. The World Wars shaped innovation, and the pandemic has shaped innovation,’ said Paul Booth OBE, in his outgoing speech as SCI President.

‘It is possible to accelerate innovation – we’ve demonstrated that.’ Paul Booth OBE, outgoing SCI President at SCI’s AGM, July 2022. Image: SCI/Andrew Lunn

The pandemic taught us a lot about ourselves. It taught me that eating my body weight in sweets was a great way to destroy my teeth, and it brought home to many the futility of the five-day commute. On a more abstract level, it taught governments and policy makers just how much can be achieved in a short space of time when necessity demands it. The vaccines that swam around our veins bore testament to this.

The pandemic has shaped innovation. Nowhere is this more apparent than in medicine. It isn’t the first awful event to provide a hotbed for change, and it won’t be the last. ‘It is possible to accelerate innovation,’ Paul said. ‘We’ve demonstrated that.’

Black Death and the bird mask

As bad as the Covid-19 pandemic was, the Black Death makes it look very tame indeed. It is estimated that the Plague, which was its worst from 1346-53, took up to 200 million lives in Eurasia and North Africa.

Amid the carnage, it is also said to have given us a system to mitigate infectious diseases with which we are familiar, including isolation periods. According to Britannica, ‘public officials created a system of sanitary control to combat contagious diseases, using observation stations, isolation hospitals, and disinfection procedures.’

The terrifying doctor will see you now.

The Plague also said to have inspired greater experimentation in pharmacology. In a sense, it also helped democratise medicine, with medical textbooks shifting from Latin to the vernacular. As John Lienhard, at the University of Houston, noted: ‘Both medical and religious practice now shifted toward the laity.’

But perhaps the most memorable advance from this time was the strange, beak-like masks worn by some doctors during the Plague. These masks were a crude (and frankly terrifying) way to protect the doctors from the disease in the air. The doctors even filled these masks with herbs in an effort to protect against pathogens.

Byproducts of the war effort

Of course, wars have also led to military innovation at breakneck speed. During the American Civil War, the Minié ball was created. It spun faster than other bullets and could travel half a mile – unlike pre-Civil War bullets, which went a mere 300 feet.

Officers of a monitor-class ironclad warship, photographed during the American Civil War.

This war also led to the ironclad warship, with plates riveted together to protect against cannonballs. However, it should also be noted that many of the most interesting war-borne inventions have ended up having little or nothing to do with military application.

The ‘cotton-like-texture’ of cellucotton led to its brand name Kotex. According to this 1920 advertisement, this ‘wardrobe essential of Her Royal Daintiness’ was available at any shop that catered to women. Different times.

World War I gave us the blood bank, the Kleenex, the trench coat, and the sanitary pad. The sanitary pad has peculiar origins. In 1914, the war resulted in cotton shortages and substitutes were needed. Kimberly-Clark executives duly discovered a processed wood pulp material that was five times more absorbent than cotton, and cheaper to make. The material was used for bandages, and Red Cross nurses realised that this material could be used as makeshift sanitary pads. The company then developed a sanitary pad – branded Kotex – made from cellucotton and a fine gauze.

Synthetic rubber and Super Glue

Material substitution also led to ground-breaking innovation in World War II. According to the National WWII Museum New Orleans, in 1942 Japan cut off the US supply of natural rubber. With the demand for rubber high, US President Franklin Roosevelt invested $700m to make synthetic rubber from petrochemical byproducts at 51 new plants. By 1944, these synthetic rubber plants were producing 800,000 tonnes of the material a year.

Duct tape was developed by Johnson & Johnson during the Second World War, and by 1972 the ubiquitous tape had reached the moon. This makeshift wheel fender repair helped the Apollo 17 mission’s lunar rover to keep lunar dust at bay.