Best known for medical imaging, ultrasound is finding application in other areas of research – from boosting chemical reactions to characterising material properties. Lou Reade reports

Extracting metals from used electric car batteries is no easy task. But now researchers in Sweden have devised a new efficient method that involves using ultrasound – the same technology that underlies foetal scans. By using ultrasound, the researchers have been able to replace strong mineral acids, such as sulfuric acid, with less aggressive alternatives – acetic and citric acid (Green Chem.; doi: 10.1039/D1GC02693C).

‘If we can use milder acids, this will make the process more manageable,’ says Xiong Xiao, a researcher in polymeric materials at KTH Royal Institute of Technology in Stockholm, Sweden.

Because the materials are relatively scarce, there is a need to recover metals such as lithium, cobalt, nickel and manganese from used batteries. In addition, manufacturers are under pressure to meet recycling and environmental targets.

The technique works because ultrasonic baths generate waves of mechanical pressure, creating microbubbles. When the bubbles collapse, this leads to local temperatures of nearly 5000°C. This raises the temperature at a microscopic level, without having to supply external heat to the mixture – which reduces the energy required by the process. ‘Ultrasound can work at the interface between solids and liquids,’ says Xiao. The extra ‘agitation’ created helps to increase the transfer of mass in the metals – allowing less aggressive chemicals to be used. The battery material is supplied as a ground powder.

Another advantage of using ultrasound and a mild acid is that it removes the need for an extra reducing agent – which can potentially reduce costs. ‘With sulfuric acid, you need to add a reducing agent in order to increase the yield,’ she says. ‘We don’t need it – which could help to save money.’

A likely reason is that the high local temperature of the bubbles creates free radicals – which act as powerful reducing agents. One type of free radical is likely to be produced when dissolved oxygen gas is split into oxygen radicals. ‘Overall, it means we need fewer chemicals in the process,’ Xiao says.

Ultrasound improves leaching performance of the mild acid more effectively than mechanical stirring. It can extract metals in around half the time – and lead to high yields. On average, the technique had a 97% rate of metal ion recovery: recovery of cobalt and nickel was greater than 99%, while recovery of lithium and manganese was 94-96%.

The process could be used to recover metals from other types of battery, such as those used in phones, says Xiao. In addition, the principle of combining ultrasound and mild acid could be applied elsewhere, such as in mining.

‘Recycling other metals from other kinds of solid waste might also be possible,’ she says.

In future, the researchers plan to scale up the process – and potentially consider using different levels of intensity and frequency to extract the metals even more quickly.

With our [ultrasound] technique, you could measure the performance of each jet engine turbine blade more quickly and accurately.

Paul Dryburgh University of Nottingham

Brain therapy

Another research area where ultrasound is making headway – to excuse the pun – is as the basis of a new method to deliver medication into the brain, something that is notoriously difficult to achieve. The blood-brain barrier is a collection of proteins shielding the brain and central nervous system from potentially harmful species such as pathogens. Unfortunately, it also filters out useful molecules, such as medication.

‘The blood-brain barrier prevents effective treatment of many brain diseases,’ says Catharina de Lange Davies, Professor of physics at the Norwegian University of Science and Technology (NTNU). For instance, it blocks cytotoxic drugs – needed by people with brain tumours – and treatments for diseases such as Alzheimer’s or Parkinson’s.

Now, de Lange Davies and her team, in collaboration with Exact Therapeutics, have devised a method called acoustic cluster therapy – or ACT. It uses a combination of ultrasound and microbubbles to open the blood-brain barrier temporarily (doi: 10.1016/j.jconrel.2021.07.019). First, small clusters of negatively charged microbubbles – attached to a positively charged drop of oil – are injected into the bloodstream. Ultrasound – directed at the brain – causes the microbubbles and oil droplet to merge into an enlarged microbubble, which has 1000 times the volume of typical ultrasonic microbubbles. The large microbubble comes into contact with many cells in the blood-brain barrier, allowing medicine – such as drugs encapsulated in nanoparticles – to reach the brain.

While a number of research teams have studied the combination of ultrasound and microbubbles to open the blood-brain barrier, de Lange Davies says the creation of such a large bubble is more effective. ‘The method increases the permeability of the blood-brain barrier and increases the uptake of large molecules and nanoparticles in the brain,’ she says. In experiments with mice, the team has shown that the blood-brain barrier closes after about one day – without causing ‘any significant damage’ to brain tissue. Testing has now begun on patients with brain cancer and Alzheimer’s disease. ‘Now we’d like to study the ACT technology in patients with malignant brain cancer,’ she says.

100

Ultrasound is proving useful for measuring elasticity, or how a material responds to a force or stress. Elasticity is difficult to measure and typically requires a single crystal to be grown, which is not always possible. Researchers say that their technique could repeat all historical elasticity measurements of the last 100 years within six months.

Enzyme reactions

Researchers in South Korea, meanwhile, are using ultrasonic waves to control enzyme reactions by mimicking the behaviour of ‘compartments’ in cells (doi: 10.1038/s41467-022-30124-x). In a real cell, biochemical reactions occur in physically separate ‘domains’. When recreating this experimentally, domains are usually separated by a physical species such as a lipid or polymer. The scientists from the Institute for Basic Science in Pohang used ultrasound to keep these domains apart, saying it is ‘as if the different layers were blocked by an invisible wall’. It relies on the ultrasound signals setting up ‘standing waves’ – leading to natural compartmentalisation.

The researchers found that oxygen from the air only dissolved in the regions where the waves augment one another: so-called ‘anti-nodes’. This led to a series of concentric circular regions that were ‘separated’ from one another. To test the system, the researchers carried out a multi-step enzyme reaction of glucose oxidase (GOx) and horseradish peroxidase (HRP). In the first step, GOx catalyses the oxidation of glucose into hydrogen peroxide. The second enzyme, HRP, then uses the peroxide to fuel a second step – oxidising colourless ABTS dye into cyan-coloured ABTS radical. The researchers proved the system worked when cyan-coloured concentric ring patterns appeared.

‘This approach will provide a new way to control chemical processes in pseudo-compartments within a solution,’ says Kim.

Elastic limit

And ultrasound is also proving useful for measuring the elasticity of some metals. Elasticity is how a material responds to a force or stress. It is difficult to measure and typically requires a single crystal to be grown and destructively tested. This can be difficult and time-consuming – and is not always possible. Now, however, researchers at the University of Nottingham have devised a technique that uses the speed of sound to measure the elasticity of metals such as nickel and titanium. As well as being non-destructive, the technique can be used to test actual components, rather than samples in a laboratory (doi: 10.1016/j.actamat.2021.117551).

‘Most materials we would like to use cannot be grown as a single crystal,’ says Paul Dryburgh, lead author of the paper, who was involved in the research as a member of the optics and photonics research group at the University of Nottingham. Jet engine turbine blades, for example, are often designed without a detailed knowledge of their underlying elasticity. To compensate, prototype parts are typically tested multiple times, to build confidence in their performance.

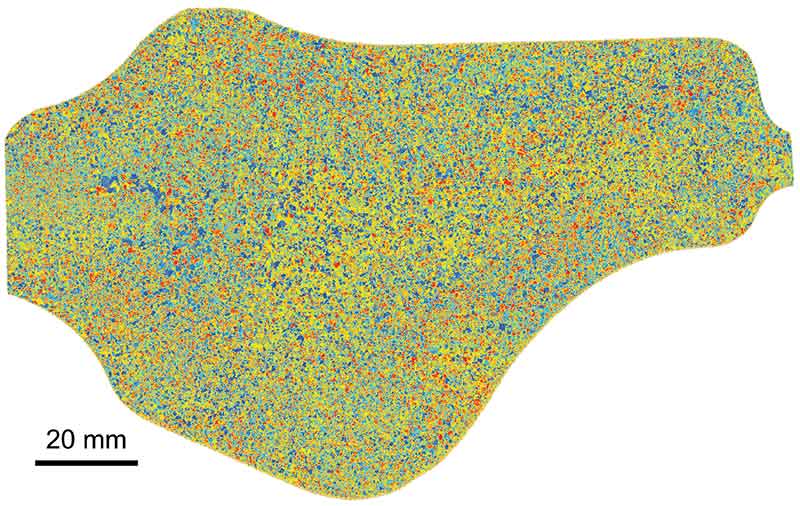

‘With our technique, you could measure the performance of each turbine blade more quickly and accurately,’ says Dryburgh. The technique is an extension of SRAS (spatially resolved acoustic spectroscopy), which the researchers call ‘SRAS++’. It uses two lasers. One fires a high-energy pulse of light at the material’s surface – heating it up and creating an internal sound wave. The second measures the speed of the sound wave through the material, which can vary.

This SRAS scan of a titanium alloy reveals its crystal structure: the colour of each region represents the speed of sound across the surface of a crystal. UNIVERSITY OF NOTTINGHAM

Engineering metals are typically anisotropic, meaning they have different properties when measured along different axes. This means that sound travels at different speeds depending on its direction through the material.

‘We propagate the wave in a different direction,’ Dryburgh says. ‘This encodes a frequency that is unique to the sound.’ It allows the technique to determine crystal orientation, which has a direct influence on elasticity. Taking multiple scans – in combination with a powerful software ‘solver’ – builds up a detailed picture of the material. Understanding the microstructure reveals details of physical properties such as elasticity.

‘By capturing around 1000 points per second we can build up a map of the part,’ he says.

The researchers say that their technique is fast enough to repeat all historical elasticity measurements of the last 100 years within six months. A key piece of ongoing research – which has already attracted funding – will be to organise a ‘round robin’ test. This will see a number of teams – in Nottingham and elsewhere – take separate elasticity measurements using different techniques.

Dryburgh sees two main ways of using the technique. One is in materials discovery, to determine the properties of promising engineering materials more quickly. The other is in a more industrial context – to test components such as turbine blades in situ.

Another potential application is testing ‘gradient materials’, which combine different materials and properties in a single component. ‘The left-hand side might have one property – such as toughness – while the right-hand side is flexible,’ Dryburgh says. ‘I can see a real demand for our technique in this type of component – as there would be no other way of measuring its elasticity.’

Gradient materials typically have varying elasticity along their length. The new technique could determine local elasticity with high ease and accuracy, he says.

Although ultrasound is not commonly used in chemistry, it has found use in areas as diverse as enzyme reactions and material characterisation. By facilitating more efficient extraction of metals from spent batteries, it is also proving its worth in the fast-growing area of environmental research.

1/2

Ultrasound improves acid leaching performance more effectively than mechanical stirring for recovering metals from old EV batteries and mobile phones. It can extract metals in around half the time – and lead to high recovery yields.

Acoustic cluster therapy (ACT) uses a combination of ultrasound and microbubbles to open the blood-brain barrier temporarily. Researchers hope it will be useful for delivering medication into the brain – for people with brain tumours and for diseases such as Alzheimer’s or Parkinson’s.

Sticker scans

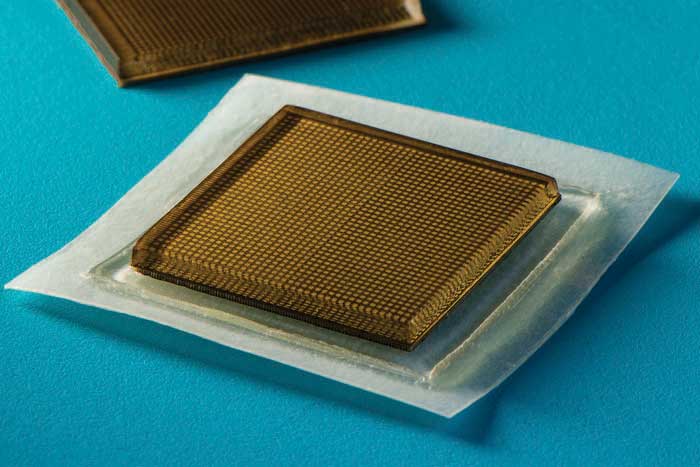

The best-known use of ultrasound is as a way of scanning internal organs and tissues. However, this is typically performed in a medical facility by a trained technician – on large, specialist equipment. Now, researchers at Massachusetts Institute of Technology (MIT), US, have developed small adhesive ‘stickers’ that can be placed onto the skin to produce medical images of the heart, lungs and other internal organs. The wearable patch, called BAUS, for ‘bioadhesive ultrasound’, has been tested on people performing activities such as jogging and drinking fluids.

‘Patches on different parts of the body would communicate with your cellphone – where AI algorithms would analyse the images,’ says Xuanhe Zhao, Professor of mechanical engineering and civil and environmental engineering at MIT, and senior author of a study in Science (doi: 10.1126/science.abo2542).

The new ultrasound sticker combines a stretchy adhesive layer with an array of rigid transducers. It conforms to the skin while maintaining transducer position to generate clear, precise images, say the researchers. Images from the stickers showed the changing diameter of major blood vessels, plus details of deeper organs – such as how the heart changes shape during exercise. The researchers were also able to watch the stomach distend, then shrink back as volunteers drank and later passed juice out of their system.

The researchers are aiming to make the stickers work wirelessly and are developing AI algorithms to better interpret and diagnose the resulting images. In future, they could be used to monitor not only internal organs, but the progression of tumours or foetal development.

‘We imagine we could have a box of stickers – each designed to image a different location of the body,’ says Zhao.

MIT’s ‘bioadhesive ultrasound’ patch sticks to the skin to provide continuous imaging of internal organs for 48 hours. FELICE FRANKEL