For decades, researchers have been trying to capture the electrons from bacteria to generate electricity in microbial fuel cells. So, are scientists finally starting to gain traction? XiaoZhi Lim reports

Bacteria are already widely exploited for treating wastewaters. By extension, microbial fuel cells (MFCs) promise to treat organic wastes in municipal wastewater or industrial effluents while simultaneously generating power. But even after decades of development, MFCs struggle to exit laboratories and see widespread use. The problem: inherently low power generation.

At the pilot scale, no MFC has yet produced enough energy to offset the energy consumption of their pumps and other ancillary equipment, says Ruggero Rossi at Johns Hopkins University in Maryland, US, pointing out that any power from MFCs must also compete with other – often relatively cheap – sources of power.

However, as MFCs begin to fill other niches such as higher value chemicals production, Rossi remains hopeful. At 300bn m3/year, domestic wastewater generated worldwide contains an estimated 600bn kWh of energy – enough to power the European chemical industry for a year. ‘If we can more effectively extract the energy from these devices, I think it’s possible,’ says Rossi.

Limiting factors

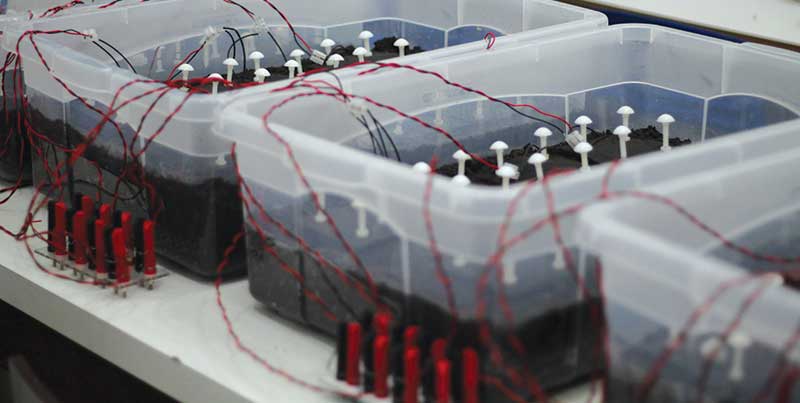

Researchers building a microbial fuel cell in which bacteria break down waste, releasing electricity in the process. Credit: OIST/Peter Ginter

Importantly, not all bacteria can produce enough energy for use in MFCs. Research centres on exoelectrogenic bacteria that occur in soils and waters. Exoelectrogenic bacteria consume organic matter and produce electrons, which they extrude outside of their cells. Typically, the bacterial activity at the anode is the most important limiting factor for power generation. But at large scales, having enough oxygen at the cathode to accept electrons is also limiting.

To address this issue, Rossi and collaborators have been testing microbial fuel cell designs with cathodes exposed to air. The team piloted a 1,400L microbial fuel cell with air-cathodes at the Tobyhanna Army Depot in Pennsylvania, US (Water Res. 2022, doi: 10.1016/j.watres.2022.118208). The microbial fuel cell removed 70% of biochemical oxygen demand from the site’s wastewater but turned just 9% of the electrons produced by the microbes into electricity. Nevertheless, the operation consumed a mere 0.13Wh/L of wastewater treated, less than half that of conventional wastewater treatment processes.

Soil-based microbial fuel cells require minimal to no energy input and can net a small amount of power that is sufficient for low-power applications, making them useful in outdoor settings or remote regions.

Another US group harnessing MFCs for wastewater treatment is California-based Aquacycl. The company employs a modular approach, with each component MFC about the size of a car battery, according to CEO Orianna Bretschger. Scaling MFCs linearly causes key parameters like mass transport, proton transport and electrical conductivity to drop, Bretschger explains. ‘You magnify every single inefficiency.’ In contrast, modular units retain the same treatment performance. But because they are small, modular systems are less suited for processing huge volumes, and better suited for treating small quantities of highly concentrated waste streams – the things that challenge the centralised wastewater treatment plant.’

One of Aquacycl’s commercial operations is at PepsiCo’s bottling facility in Fresno, California, US. The facility discharges about 140-150,000 US gallons – over 0.5m L – of wastewater/day. But when Bretschger’s team analysed PepsiCo’s wastewater, ‘really only about 3% of that volume, so upwards of 5000 US gallons (around 19,000L) a day, was responsible for 60% of their sewer bill,’ says Bretschger. Only when the facility needs to dump a bad batch or returned goods will spikes occur in the wastewater’s organic matter. Aquacycl is currently treating the facility’s wastewater with a 40ft shipping container of MFCs, removing 800-1600kg of biochemical oxygen demand/day, according to Bretschger.

Aquacycl is also working to treat the wastewater produced by tank storage giant Vopak. In this case, the organic matter is largely synthetic hydrocarbons from washing tanks, but the microbes consistently brought regulated chemicals like benzene, naphthalene, phenols and ethers below detection level, Bretschger says. While Aquacycl’s MFCs still consume more energy than they produce, she is hopeful they can soon offer net-zero waste treatment.

Limiting factors

Bacterial activity occurring at the anode of a microbial fuel cell is the most important limiting factor for power generation. But at large scales, having enough oxygen at the cathode to accept electrons is also limiting.

600bn

The 300bn m3/year of domestic wastewater generated worldwide contains an estimated 600bn kWh worth of energy.

Soil-based MFCs

Soil-based MFCs are another simpler variation of MFCs. Here, the soil is not just the source of exoelectrogenic microbes, says Mirella Di Lorenzo at the University of Bath, UK. It also serves as the source of fuel, the electrolyte and the separator between the anode and cathode, so there is no need for a membrane or pumps. Soil-based microbial fuel cells require minimal to no energy input, making them useful in outdoor settings or remote regions, she explains. In 2019, Di Lorenzo and her team successfully tested soil-based MFCs at a primary school in Icapui, Brazil (J. Pow. Sour. 2021, doi: 10.1016/j.jpowsour.2021.230591). Adopting a modular approach, the researchers stacked multiple cells to produce enough electricity to disinfect 3L of water/day. The system was adequate for basic water disinfection, and simple enough for primary school students to operate and monitor, Di Lorenzo says.

Soil-based microbial fuel cell stacks can generate enough electricity to disinfect 3l of water per day.

Credit: Mirella Di Lorenzo

One surprise finding was that the system worked better outdoors than in the laboratory, Di Lorenzo says. This was attributed to the use of real soil and real water from a pond as opposed to compost and sterile water in the lab, as well as warmer and relatively humid conditions in Brazil. Di Lorenzo and her team are now working to optimise soil-based MFCs for different environmental conditions and climates, while working towards commercialisation.

‘Exoelectrogens are naturally occurring in almost every type of soil on earth,’ says Colleen Josephson at the University of California, Santa Cruz, US, who hopes soil-based MFCs could help power outdoor sensors for agriculture. Agriculture accounts for about 70-80% of the globe’s freshwater consumption, she says. Precision agriculture could help, but it needs a network of sensors that can measure parameters like soil moisture and temperature, and communicate this information back to a central system, which can then use it to control irrigation. All these components require power, which farms and fields usually lack. ‘If you look at who deploys sensor networks, they are only for the most valuable crops,’ Josephson says.

In 2021, Josephson designed an outdoor sensor that could run for five years on a coin cell battery. ‘Even though they have a long lifetime, it’s still limited,’ she says. So, when Josephson was introduced to soil-based MFCs, she was immediately intrigued. Wireless sensing technology had recently improved to require less energy – just sub-microwatts of power – which soil-based MFCs can meet (Getmobile: Mobile Computing and Communications; doi: 10.1145/3568113.3568117). ‘Our early results have shown success in harvesting small, but meaningful amounts of power.’

A major limitation was the cost to trial microbial fuel cells in the field – over $1500/microbial fuel cell, Josephson says. The group is now working on a data collection system that will reduce the cost to less than a tenth (doi: 10.1145/3560905.3568110). The team is also testing different geometries of soil-based MFCs.

Soil-based microbial fuel cell staged for deployment at the UC Santa Cruz farm. The waterproof box contains power monitoring and communication equipment.

Credit: Colleen Josephson

Chemicals production

Another way to make MFCs more competitive economically is to harness them for higher value chemicals production, such as hydrogen or biogas. At Johns Hopkins, for example, Rossi is collaborating with researchers at the US National Renewable Energy Laboratory (NREL) to harness the electrons from exoelectrogens to produce hydrogen from lignin. NREL researchers have already worked out how to ferment lignin, but are not able to use it completely, Rossi explains, leaving behind a feedstock rich in organic acids. ‘We take these organic acids and we run it to a microbial electrolysis cell,’ Rossi says. In this case, rather than reducing oxygen at the cathode, the team is attempting to reduce water to hydrogen. Because the microbial activity already produces electrons, the reaction requires just a small boost of electricity, compared with normal water electrolysis.

‘At this point, a major breakthrough has to be made to adapt [microbial fuel cells] to a power generation technology.’

Xiangfeng Duan, department of chemistry and biochemistry, University of California, Los Angeles, US.

MFCs could also help increase the yield of biogas, a mix of methane and light hydrocarbons, from anaerobic digestors. In anaerobic digestors, microbes turn the sludge from wastewater treatment facilities into biogas, but they are fussy and don’t handle fluctuations in feedstocks well. MFCs could help absorb ‘shocks in the feedstocks’ by producing the fatty acid streams that anaerobic digestors prefer, according to Bretschger, who is currently seeking industrial partners to perform tests. Based on early data, she estimates that MFCs could help increase biogas production by 30-50%.

Detail of hydrogen fuel cells.

Elsewhere in the hydrogen economy, MFCs could complement chemical fuel cells and support hydrogen transport. Chemical fuel cells that run on hydrogen work well, but transporting hydrogen gas comes with efficiency losses due to compression. Small organic molecules such as methanol, ethanol, or formic acid could serve as liquid hydrogen carriers, but traditional chemical catalysts are not good at converting these organic liquids into electricity, says Xiangfeng Duan at the University of California, Los Angeles. US. Chemical fuel cells powered by such liquids usually require a very high over-potential, he says, adding that MFCs could be much more effective in extracting electrons from these organic liquids.

Judging by the ongoing research, there appear to be plenty of opportunities for MFCs. As for their potential to contribute to overall energy generation, researchers remain sceptical. ‘At this point, a major breakthrough has to be made to adapt this to a power generation technology,’ says Duan.

Electricity from plastic

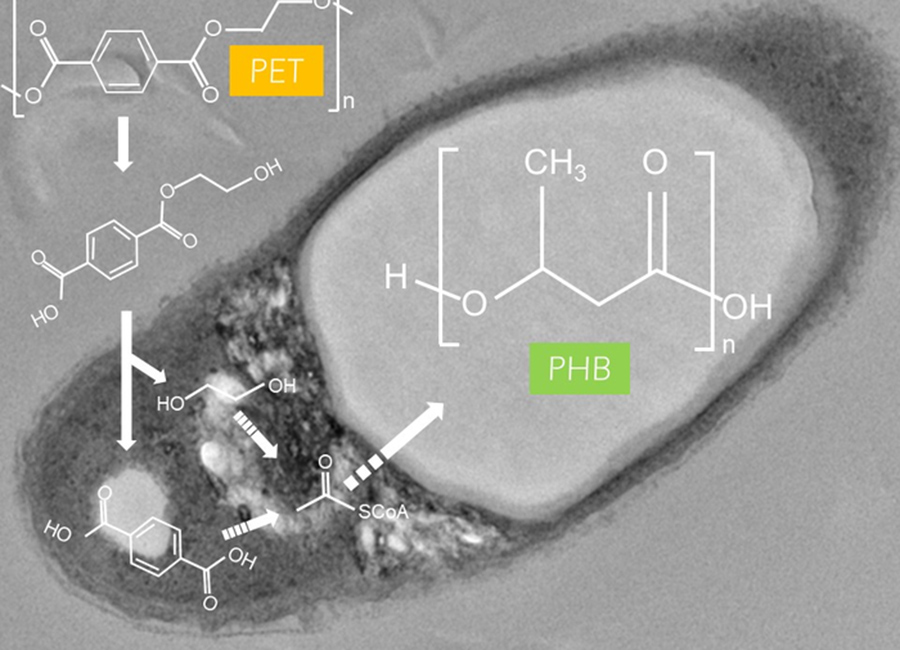

Ideonella sakaiensis grown on poly(ethylene terephthalate) (PET) accumulates poly(3-hydroxybutyrate) (PHB). Credit: Shosuke Yoshida

Accumulation of plastic waste in the environment is a major worldwide problem. In 2016, researchers identified Ideonella sakaiensis in sediment near plastic recycling plants in Japan – a bacteria that breaks down polyethylene terephthalate (PET). A team of researchers led by Erwin Reisner at the University of Cambridge, UK, combined the PET-digesting capabilities of I. sakaiensis with an exoelectrogen’s ability to produce electricity in MFCs (Angew. Chem. Int. Ed. 2022, doi: 10.1002/anie.202211057).

I. sakaiensis was first found in aerobic (oxygenated) conditions, releasing CO2 and water from its PET consumption. Reisner’s team scoured its genome for anaerobic metabolic pathways and found it could ferment PET anaerobically to produce acetate. Then, they co-cultured I. sakaiensis with Geobacter sulferreducens, a soil bacterium known for producing electricity efficiently by oxidising acetate in MFCs. Working in tandem, G. sulferreducens can consume the acetate produced from I. sakaiensis fermenting PET, together producing a few hundred µA of current from 23mg of PET in six days.

Soil-based microbial fuel cells require minimal to no energy input and can net a small amount of power that is sufficient for low-power applications, making them useful in outdoor settings or remote regions.

Anodic shortcut

‘Just like we cannot eat too fast, microbes cannot consume the organic matter too fast,’ says Ruggero Rossi at Johns Hopkins University in Maryland, US. To maximise microbial activity in an MFC, anodes are typically designed in the shape of a brush to maximise the surface area bacteria can attach to.

Xiangfeng Duan and his team have developed a novel strategy that provides a ‘shortcut’ for microbes to transfer their electrons to the anode (Science, doi: 10.1126/science.abf3427). The researchers first observed the way electrons travel through a microbial biofilm, noting that the biofilm’s electrical conductivity was simply too low. ‘Instead of relying on the intrinsic transport channels of microbes, we allow it to reduce some silver ions,’ Duan explains. By introducing silver ions into the electrolyte, any electrons the microbes produce quickly reduce the silver ions into metallic nanoparticles. Some nanoparticles become embedded in the bacterial cell membranes, and even extend outwards to the anode, providing ‘a much better connection’ from the bacteria to the external circuit, Duan says.

Based on this design, the researchers harvested an unprecedented 81% of the bacteria’s electrons as electricity. But Duan hopes to improve the power output by another order of magnitude.

Chip incompatibility

Apart from the engineering challenges, MFCs also suffer from incompatibility with conventional energy-harvesting chips. To generate electricity from a varying power source, an energy-harvesting chip needs to first condition this power into more steady and standard voltage and current levels that traditional electronic components can draw upon.

Colleen Josephson in Santa Cruz collaborated with Pat Pannuto at the University of California, San Diego, US, to investigate how conventional, off-the-shelf chips behaved with MFCs (2022 IEEE Int. Symp. Circuits Syst., doi: 10.1109/ISCAS48785.2022.9937297). ‘We saw some really unexpected behaviour,’ says Josephson. With a standard 2.2kΩ resistor, a soil-based MFC can produce around 100µW of power. But the conventional energy-harvesting chips pick up only 20µW.

The researchers think the fault lies with the chips’ algorithms, which are usually optimised for solar or wind power. ‘It doesn’t work well for the microbes,’ Josephson says. ‘That’s not terribly surprising because you have a biological, organic source of power versus something that’s come purely from physics.’

Currently, Pannuto’s student Gabriel Marcano is working with Josephson’s students to develop algorithms to harvest electricity from soil-based MFCs more effectively.