BioNTech has completed the construction of its first proprietary plasmid DNA manufacturing facility, located in Marburg, Germany. It will be used by the company to produce plasmid DNA for clinical product candidates and commercial products in the areas of cancer, and infectious diseases.

Plasmid DNA is a starting material for the manufacture of mRNA-based vaccines and therapies, as well as cell therapies. The €40 million investment at Marburg is part of a long-term development plan by BioNTech for the site.

The facility comprises two plants, which cover both clinical and commercial scale plasmid DNA production. The clinical plant has been in operation since August 2022, while the commercial plant is due to become operational by the end of 2023. The company anticipates that it will manufacture enough plasmid DNA to be used as the starting material to produce mRNA for several hundred million doses or therapies each year, depending on the product or the product candidate.

German Chancellor Scholz and Augur Sahin at the Marburg facility. Image: ROCKSTEIN Fotografie/BioNTech

BioNTech added that as well as the established commercial production of the Pfizer-BioNTech covid-19 vaccine, there are plans to develop the Marburg site to include a technology hub for innovative manufacturing solutions.

Visiting the new facilities, Chancellor of the Federal Republic of Germany, Olaf Scholz said: ‘The pandemic has proven Germany’s capability as a location for innovation and manufacturing of medicines. Germany and Europe are becoming more resilient by building local value chains. BioNTech’s investment is very good news.’

CSIRO brings AI to bear on neurodegenerative disease

CSIRO researchers are using machine learning to advance Alzheimer’s research. Image: CSIRO

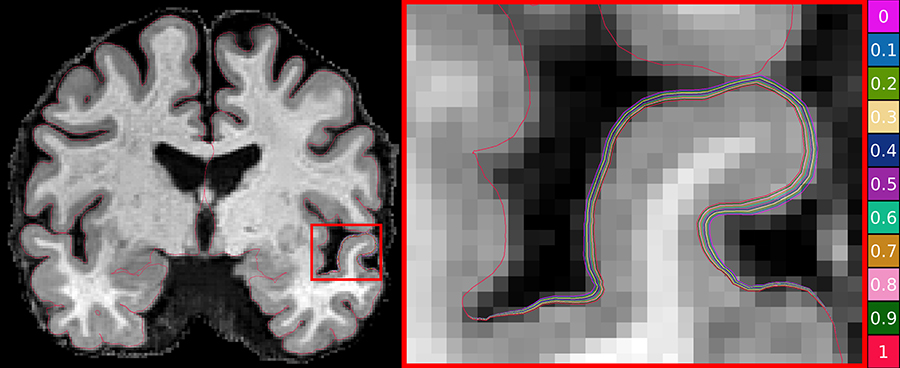

Scientists from Australia’s national science agency, CSIRO, in partnership with Queensland University of Technology have used artificial intelligence (AI) to develop a world-first benchmark for measuring brain atrophy in neurodegenerative diseases such as Alzheimer’s.

Existing methods, such as MRI scans, to assess the onset and progression of Alzheimer’s are challenging, as changes in the thickness of the brain’s cortex are extremely small. Filip Rusak, CSIRO research scientist said: ‘Using the power of machine learning we were able to produce a set of artificial MRI images of brains with predefined signs for neurodegeneration in the cortex region.’

This technique now allows researchers to set the amount and location of brain degeneration they want to compare against so that they can get a clear picture of what method of cortical thickness quantification performs the best.

Johnson Matthey partners with Plug Power on hydrogen

Looking to accelerate the global green hydrogen economy, Johnson Matthey and Plug Power, a US-based hydrogen fuel cell systems company, have formed a strategic partnership in which Johnson Matthey will supply catalysts, membranes and catalyst coated membranes (CCM) to Plug Power.

The partners will invest in what is said will be the world’s largest CCM facility in the world, starting out at 5GW and rising to 10GW over time. The planned facility will be located in the US and is expected to be operational by 2025.

Liam Condon, CEO of Johnson Matthey commented: ‘By bringing together one of the largest green hydrogen and fuel cell companies in the world, with JM’s technology and manufacturing capabilities, we’re creating volume and scale for green hydrogen that hasn’t existed until now.’

Dow outlines cost saving plan and collaborates on sustainable packaging

Meanwhile, looking to reduce costs, Dow has outlined a ‘series of targeted actions’ aligned with its plan to achieve $1 billion in cost savings in 2023. The actions include: shutting down select assets while ‘further evaluating Dow’s global asset base, particularly in Europe, to ensure long-term competitiveness and enhance cost efficiency, reducing purchased raw materials, logistics and utilities costs, and aligning spending levels to the macroeconomic environment.’

‘We are taking these actions to further optimise our cost structure and prioritise business operations toward our most competitive, cost advantaged and growth-oriented markets, while also navigating macro uncertainties and challenging energy markets, particularly in Europe,’ said Dow Chairman and CEO Jim Fitterling.

In a separate development, Dow has said that it will collaborate with LVMH Beauty, a division of luxury goods conglomerate LVMH, to accelerate the use of sustainable packaging across the perfume and cosmetic products business. Dow said that the collaboration would allow both bio-based and circular plastics to be integrated into several of the multinational’s beauty product applications without compromising functionality or quality of the packaging.