Bright SCIdea is SCI’s long-running entrepreneurial competition, which sees teams of university students pitch their science-based business innovations to a panel of judges, with the winning team walking away with £5,000.

This year’s final – the seventh time the challenge has been run – took place at SCI’s London HQ on 18 March, and marked the culmination of months of hard work and preparation by six teams of finalists. The competition has now seen over 300 students from across the globe receive training as part of the programme, while the poster session held alongside the final included teams from Canada and Australia as well as the UK.

SCI CEO Sharon Todd welcomed the teams to the event. “We are about the acceleration of science out of the lab for the benefit of society and all of your pitches today and all of your business plans are generating ideas for exactly that purpose. It is about using science and engineering to address societal challenges, it’s about diversity of teams, disciplines, cultures and thought, and it is about collaboration.”

SCI’s annual entrepreneurial challenge was judged by Lucinda Bruce-Gardyne, founder of Genius Foods; Liz Rowsell OBE, chief technology officer at Johnson Matthey; Victor Christou, managing partner at Hotdog Capital and Robin Harrison, Vice President Platform Technology & External Innovation at Synthomer.

Each of the teams pitched their idea in turn, and then took questions from the judges.

ReefCycle

Looking at the problem of the sustainable restoration of coral habitat ReefCycle, a team from the University of St Andrews, was the first to take the stage and make their pitch.

Coral reefs are facing die-offs at an unprecedented rate which makes restoration efforts crucial but these efforts can rely on unsustainable materials like PVC piping, nylon ropes and metal rebar to build a framework for the coral to grow against. “Would you yourselves throw plastics into the ocean?’ the team asked.

“We know that coral restoration is important but we need a better way.” To address the problem, the team has come up with the concept of using a natural material, upon which the coral could be supported and allowed to grow. “Current coral restoration activities lack a sustainable material. ReefCycle proposes to use a natural biodegradable and cost-effective substrate,” the team said.

The team explained that coral restoration projects are well funded and supported by a range of global and non-governmental bodies. “There are billions flowing into this space” but monitoring of these projects is not always well organised, the team added. The team explained that by taking waste products from local businesses such as restaurants as part of their idea, there was the possibility to create a local supply chain with suppliers receiving certification and recognition of their support in regenerating the local coral.

EleCure

Tackling the problem of chronic wounds was behind the business idea of the second team to pitch, Team EleCure from King Fahd University of Petroleum.

Chronic wounds are wounds that linger for months causing distress for patients and significant costs for healthcare providers. The NHS spends billions on treating chronic wounds each year, the team noted, largely on lower limb wound care. An estimated 15% of people with diabetes develop chronic wounds annually according to data quoted by the team – as many as 88 million people per year. EleCure set out their concept of bandages combined with electrotherapy which would help speed the rate of wound healing particularly for elderly patients and those with diabetes.

“With an ageing global population and a rise in diseases such as diabetes, the incidence of chronic wounds was set to increase around the world,” Team EleCure said.

The team said that their concept would reduce hospital visits as well cutting the costs to hospitals and patients. The team added that the bandages would also allow wounds to monitored remotely so that further treatment can be recommended if needed.

The judges applauded the teams very commercial outlook and asked what the patient experience would be like - and how they would be instructed in the use of a Team Elecure’s high-tech bandage. The team explained that the bandage can be easily applied, and instructional videos would ensure its correct use. In addition, connections with trained clinicians would allow for regular assessment of the wound.

Team ElecCure was also asked about the safety of their product as its disposal would present a biohazard. The team explained that this hazard was covered using special bags for disposing the bandages.

SoilMark Analytics

Tackling sustainable soils and regenerative agriculture, Team SoilMark Analytics from the University of Nottingham, set out their solution for helping farmers get accurate data on their soil health. Describing a simple handheld device that provides data on moisture, macro-nutrients and pH, the team said that “Existing methods for testing soils are not useful for farmers in remote locations. In addition, existing methods are expensive.”

The SoilMark Analytics team explained that their device uses algorithms which when analysing soils would provide actionable outcomes. The team set out three ways in which their product would support farmers: the device could be used offline, the price would be lower than the cost of standard testing protocols and finally it would be robust enough to operate in a range of conditions.

“The market potential of our product is substantial,” said Team SoilMark Analytics. “We would first focus our efforts on small holders but also seek to partner with governments and organisations supporting small farmers,” the team said.

Recognising the positive impact Team SoilMark Analytics’ idea could have on the agricultural sector and sustainability, the judges asked how they intended to ensure that their system could stay ahead of the market. “We will look to include analysis of micronutrients, currently it tests for macronutrients. We would also develop it provide insights on soil biodiversity,” the team explained.

mPHACT

Team mPHACT from Imperial College, London said their time at university had made them realise how much plastic they use on a daily basis from pippets to plastic gloves. “We realised our own impact and contribution to plastic waste and so with our strong biochemical and engineering background we decided to dive deeper into looking for solutions for plastic waste,” the team explained in their pitch, which involved taking waste plastic and converting that into useful biodegradable plastics

Worldwide there are 34 million metric tonnes of PET plastics produced and consumed every single year, with only 9% of that being recycled, the team pointed out. “And although a lot of effort is being focused into creating biodegradable plastics none of that addresses the issue of the risks and challenges that we face due to the accumulation of plastics in our fields and oceans.”

The team said they would use the investment to start their pilot phase and optimise their process and said they wanted to do their further development on Teesside because of the close proximity to plastics recycling needed as a feedstock and a local workforce skilled biotechnology.

Judges asked how the teams idea stood up against the potential rivals and how they could protect their intellectual property against the competition. The judges were also pleased the team had considered locations and availability of feedstocks and also how they would fit in with the wider business ecosystem – and the scale of their ambition. But they also asked questions about the go-to-market challenges of a new process and a new product, and whether the team had chosen the right target market – medical usage - for their new offering rather than a different usage such as packaging.

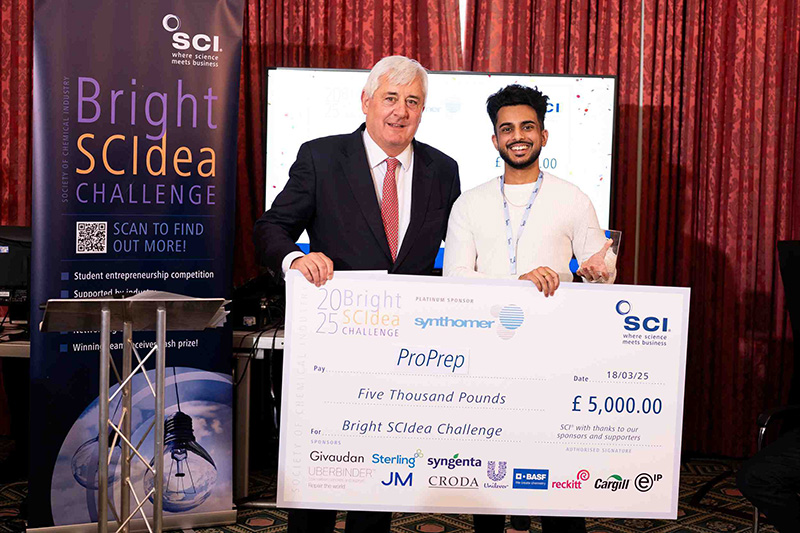

ProPrep

Protein-based medicines have the potential to tackle countless diseases however they are incredibly difficult to make, said Christopher D’Souza, presenting on his own for the ProPrep team.

ProPrep is developing protein production technologies to reduce cost and increase productivity for scientists who produce proteins to detect, treat and prevent diseases. “Ultimately this is to accelerate the research and development of protein-based medicines,” D’Souza said.

“The problem that we are trying to solve is that to make these medicines, you first need to make the proteins and to make the proteins is incredibly costly in terms of your time your resources…and your sanity,” he explained. On average it takes about 30 hours of manual work to produce the proteins.

There is a lot of interest and funding in protein-based medicines now which D’Souza described as a “protein-based medicine gold rush.” The protein production market is strong and forecasted to reach 84 billion by 2030

The judges asked about how the team had set the price point for their product and asked questions about other ways of monetising the product, as well as asking ProPrep what was stopping competitors doing the same thing, and how would the team protect its intellectual property.

NanoGuard

The final pitch of the day saw Team NanoGuard explain the current challenges around catheterisation in hospitals. One in four long term hospitalisations require catherisation and of those people 25% do develop infections the team said. The team’s business idea is focused on mitigating these infections and reducing the threat of antimicrobial resistance. The team has created a catheter product that aims to target the bacteria which lead to urinary tract infections. This would have the benefits of reducing the cost to catheter patients and also reducing the spending on antibiotics. Regular catheters cost about £10 per unit and these have to be changed every 24-48 hours in patients. A product that lasts much longer and doesn’t require the use of antibiotics could save time for nurses and money for health care providers as there is a potential market of 4.25 million patients annually, the team said.

The judging panel asked questions about how the efficacy of the catheter could be measured, which the team said would be proved during testing and R&D. The judges also asked about manufacturing plans and also questions about the business model and suggested that the team consider pricing based on the value they delivered - rather than just the costs of manufacture.

And the winner is…

SCI’s President Paul Drechsler revealed the results of the judges’ deliberations.

“What we heard this afternoon were so many different examples of your brilliant collaboration, your brilliant team working and your innovation, coming up with solutions to some of the world's most important problems,” Drechsler said. “You were fabulous and what you have done is lifted my confidence because the future is in excellent hands.”

Third place went to SoilMark Analytics. Second was team mPHACT and the winner was ProPrep - which also won the audience vote on the day.

“I am absolutely ecstatic; a lot of hard work went into this so it’s nice to get the reward at the end of the day. I also met a lot of cool people,” ProPrep’s Christopher D’Souza told C&I after the announcement. “The whole thing is so well structured. I learned a lot along the way, I think one of the main things was that it's good how they helped us transition from scientists to people in the commercial world and that was valuable. There was so many different workshops and mentorships, speaking to different people along the way who were all there to support us, which was absolutely incredible.”

Asked what he would tell someone considering applying for the next Bright SCIdea D’Souza said: “If you have an idea and you’re feeling a little bit shy about the idea and you’re not sure if it’s going to work or not work: please apply. Because you never know what’s going to happen through this process.”