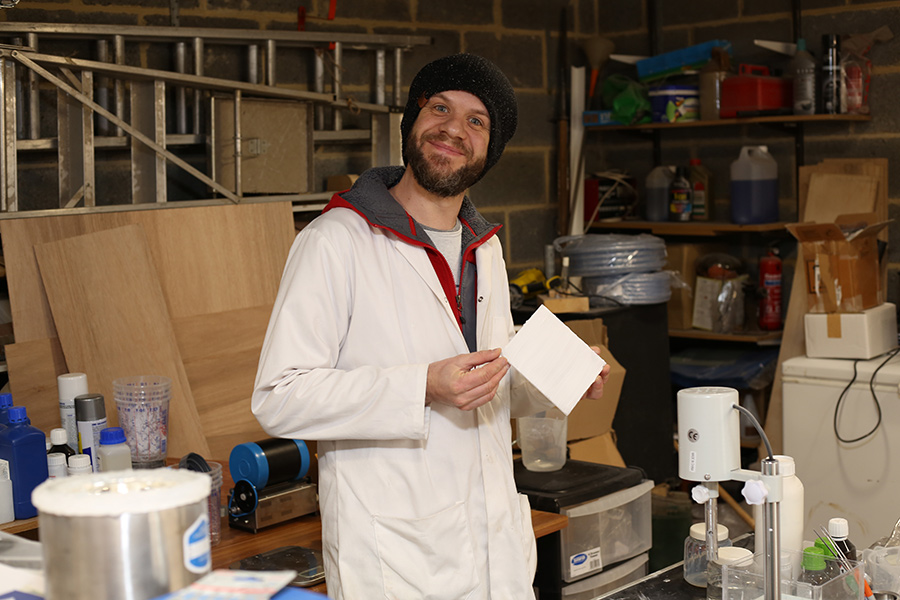

Simon Frost

An ultra-cooling paint that a father and son began developing in their garage has attracted international investment.

When father and son Howard and Robert Atkin started developing an ultra-cool paint in their garage in Yorkshire, UK, they were motivated by nothing less than the future of the planet.

‘When you look at global warming, especially as a parent’, Robert says, ‘You think about the impact that it’s going to have on your family – your children, grandchildren and beyond. So, we both really felt morally obliged to do something, seeing as we have a background in new product design.’

‘You can’t air condition your way out of a warming world,’ Howard adds. ‘That just creates more emissions. You get localised heat islands because of all the heat being kicked out of the buildings – it can actually increase the local temperature.’

While air conditioning can keep a building cool inside, the environmental cost is considerable – both raising the local temperature and contributing significantly to global emissions.

Just two years since they began working on their idea at the bench (in this case, a wallpaper pasting table) during lockdown, the father-and-son have now teamed up with a US-based venture accelerator to scale up their patent-pending technology. They’ve been testing their product in India and in June 2023 were in Singapore to workshop with other innovators from around the globe.

They’ve named the company Pirta – an Inuit word for ‘blizzard’ – in part, a reference to the temperature and crystalline structure of snow that gives it its white appearance; but also a reminder of the disproportionate effect climate change has on nomadic peoples, who, Howard notes, are the least responsible for it.

Pirta took inspiration from the passive cooling strategies found in nature to deliver a heat-repellent coating that could find application in countless industries where cooling is required – from construction, shipping and logistics to agriculture and energy – to reduce the reliance on active cooling systems.

Howard explains: ‘Take silkworm grubs, shellfish – these things can’t run away when the tide goes out or cover can’t be found. When the sun’s baking them, they have to have means of keeping themselves cool, or they’ll quickly die.

The silkworm has evolved to keep itself cool. Howard and Robert Atkin took inspiration from natural cooling strategies when developing their paint.

‘Over millions of years, these natural cooling systems have become tried and tested and quite sophisticated, at a minute level. This is very interesting to product design engineers and developers. We thought, if we could take these kinds of systems that are in nature and turn them into a coating, so you could treat your building like the silkworm protects itself, that would be fantastic.’

They had the idea, the motivation and, with a background in the insulation industry, plenty of expertise in heat transfer and design. ‘We knew what was required physically. The difficult part is meeting the requirements of a paint – something you can just stick a brush in and slop on. That was the steep learning curve,’ Howard says.

Not only did the duo have to learn about paint manufacture and the chemistry of formulations, dispersions and additives; to maintain confidentiality around their cooling technology, they had to work with suppliers and take advice and learnings on manufacturing practices without giving away any of their secrets. ‘We have our own kind of special sauce in there, which is what we have the patent pending for,’ Howard says.

The early research and development was carried out in Howard's garage during Covid lockdown. Image: Pirta

They decided early on that the paint had to be water based, too. ‘We didn’t want any volatile organic compounds in this, because you can’t try and save the world from one problem while making another one worse. It had to be water based, which is what we’ve achieved,’ Howard notes. ‘We had to design it so that it could be manufactured without some kind of ‘wacky’ new production method, too,’ Robert adds. ‘We want the fewest barriers to market.’

But how did they explain how the paint works when they were pitching to investors? The basic premise of the paint is that it is both highly reflective and highly emissive, so it loses more heat than it absorbs. ‘It’s incredibly reflective in the UV and the visible, and pretty reflective in the infrared as well. But it’s as emissive as a black surface. So not only does it reflect – it can shed its heat and emit it back into space,’ Robert explains. ‘I’m not sure we can go into much more detail on that now, though.’

Through reflection and refraction, the irregular structure of Pirta reflects light and heat away from a surface but also allows heat to move through millions of facets within the paint, and away from the interior of a structure. While most paint gets its smooth finish from a solid air-free surface, Pirta's is from a consistent network of tiny crystals, like fresh fallen snow.

Howard and Rob (front) with University of Leeds collaborators. Image: Pirta

Lab tests – around 800 of which have now been carried out in collaboration with the University of Leeds in the UK – showed a peak reflectance of 99.82% across visible and ultraviolet light spectrums. The paint formula’s solar reflectance index (SRI), recognised as an industry standard for measuring material thermal properties, was valued at 116.8 – a scale with a theoretical limit of 130, with most materials falling between one and 100.

‘We’re being very careful to have the performance validated and checked,’ Howard says. ‘We’ve had another university in southern India do some blind tests, hooking up some data logging software and taking some temperatures, putting them out in the sunshine, then sending us those results back. So, it’s completely unbiased – we wouldn’t just want to report on the performance as we recorded it.’

Pirta plans to publish research in a peer-reviewed journal later in 2023.