BY LOU READE

Throwing viable, edible food away is a moral and ethical problem that needs urgent attention. Now researchers are turning this food ‘waste’ into valuable food additives, bioplastics – and even energy. Lou Reade reports

The statistics surrounding food waste are deeply worrying. Up to 40% of the US food supply is wasted, the US Department of Agriculture estimates, while few crops are 100% edible – with skins, peels and other inedible elements typically discarded and sent to landfill. That adds up to a lot of rotting food matter, which in turn generates methane and contributes to the burden of global warming.

But for many researchers, food waste is also potentially a valuable resource. ‘If we can use food waste as a feedstock, we don’t pay for it – and actually earn money by accepting it from the producer,’ says Drew Wang, assistant professor in the department of biological systems engineering at Virgina Tech, US. On top of that, the waste can then be converted to a high-value, saleable product.

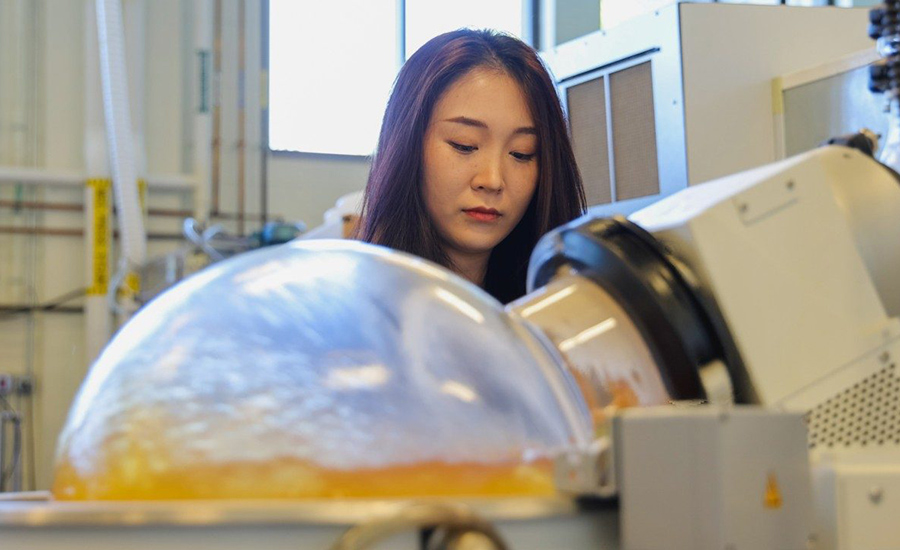

Wang and colleagues are using microorganisms to convert food waste, diverted from landfill, into ‘biological oils’ to make a biodegradable polymer called polyhydroxyalkanoate (PHA). PHAs can in turn be used to make home-compostable products such as bottles and packaging films.

Fujunzhu Zhao, a Ph.D. student, works in Zhiwu "Drew" Wang's lab. Wang's team is working to convert food waste into sustainable bioplastics. Photo by Luke Hayes for Virginia Tech.

‘We’re trying to solve two challenges at once: food waste and plastic pollution,’ says Wang, adding that landfills are full of both food waste and oil-based plastics – which survive for many hundreds of years.

Virginia Tech has received a $2.4m grant from the US Department of Agriculture to test the scalability and feasibility of its idea over the next three years. ‘The goal isn’t really to make a bottle, but to discover the best-selling price for PHA,’ says Wang. For comparison, the project analysed the economics of polylactic acid (PLA) – the most widely used bioplastic. It found that the main reason for PLA’s high cost was the feedstock: it is made from ‘human food’, he says – typically sugar cane.

PHA’s main advantage is being ‘100% biodegradable’. Unlike PLA, it requires no ‘special’ conditions in order to decompose, Wang says, adding that: ‘PHA is also broken down in the sea, but PLA is not.’

The researchers receive three types of food waste:

- Cooking oil – which is converted relatively easily into PHA;

- Mixed waste – which undergoes ‘dark fermentation’ to convert it into volatile fatty acids (Wang says vinegar is a typical example). The nutrients in this fermented liquid are used to ‘feed’ bacteria, which convert them into PHA; and

- Very salty food waste – converted using a halophilic (salt-loving) bacteria species found in the Mediterranean Sea (RSC Advances, DOI: 10.1039/C7RA09652F), since regular microbes would not survive the high salinity, Wang explains. Here, the mechanism behind PHA production is cell survival, he says; the bacteria produce PHA – in the form of an oil drop – in order to withstand the osmotic pressure. The PHA can be extracted by soaking the cells in fresh water, which causes them to burst. The oil is then extracted using an organic solvent. This process is quite labour-intensive, with different culture conditions producing different amounts of PHA.

The team intends to use the new funding to scale up from 1l to a 100l pilot scale fermenter. The aim is to make 5kg of PHA – allowing them and their collaborators to test its physical properties. The process will also need to be optimised. ‘This stage of the project is about engineering,’ Wang says. ‘We need to work out how to separate the cell from the water in an economical way – be it through membrane technology, flocculation or another method.’

Heat is on

Foods such as fried bananas retain their heat for a long time because of the presence of esters.

Waste food products, meanwhile, may also one day form the basis of an ingenious system to store heat – rather like a battery. Norwegian research organisation SINTEF has devised a compact heating and cooling system that relies on phase change materials (PCMs) – in this case, esters – which could be made from discarded cooking oil.

‘Our system can replace a heat exchanger or a water heater,’ says Galina Simonsen, a senior research scientist at SINTEF.

She says that foods such as fried bananas retain their heat for a long time because of the presence of esters. The principle behind this is well understood. When a material freezes – or crystallises – it emits latent heat. In reverse, it melts when it absorbs heat. PCMs that melt/solidify at around 32°C can be used to turn cold water into warm water when the two are mixed. Alternatively, they could cool a warm room.

‘We’ve found esters that melt around this temperature, but we also wanted a PCM that can store the maximum energy,’ Simonsen says.

Other PCMs such as salts or sugars have superior performance, but are typically more corrosive and less sustainable. An ester-based PCM with a higher melting point could be used, for example, in industrial settings.

For now, the team has built a prototype system and is using an ester called methyl palmitate as the PCM that heats water. By bringing the two into contact, heat is transferred from the PCM to the water. One problem is that the water droplets and PCM begin to form a stable emulsion. This delays separation of the two fluids, so the warm water does not emerge from the system with a high enough flow rate. If the stable emulsion keeps growing, it can extend through the whole system – and potentially leak from the bottom.

‘This will also lead to loss of the PCM, as it is now part of the emulsion itself,’ Simonsen says.

Once the emulsion problem has been solved, the researchers intend to investgate converting waste cooking oils into PCMs.

‘This is achieved by trans-esterification – the same way biodiesel is made,’ Simonsen says. Waste oils would be collected, filtered and purified, then converted into suitable esters. This would require a specific type of alcohol. The process is likely to be complicated by the mix of oils, she adds, pointing out that Norway is home to around half a million wood cabins – many of which do not have electricity. The SINTEF system could prove to be a sustainable way to heat them, by storing solar energy in the summer and emitting it in winter.

AI improvement

In the UK, researchers are planning to harness AI technology to improve how anaerobic digesters break down products such as food waste into biogas. The project, led by Surrey University, is supported by a £1.4m grant from UK Research and Innovation. It will investigate the impact of using different types of waste, such as food, wastewater and animal manure, to feed anaerobic digestors.

‘The challenge of complex bioreactors is their lack of predictability and the dynamic environment within digestors,’ says Michael Short, principal investigator at the university’s school of chemistry and chemical engineering.

Using a variety of sensors and information from sampling the microbes, the team will create virtual copies or ‘digital twins’ of the digestors. AI systems will then analyse the impact of each feedstock. The project aims to increase biogas yields by 20%. ‘We want to know how each species of microbe reacts to different food, and to the other microbes,’ says Short. ‘The knowledge we get from the digital twin digestor will start to address this uncertainty.’

The UK has around 650 anaerobic digestors, which use microbes to degrade waste – mainly from agriculture and the food supply chain – into biogas, including methane. This is then purified to create a carbon-neutral source of natural gas, reducing dependency on imported fuels.

Net profit

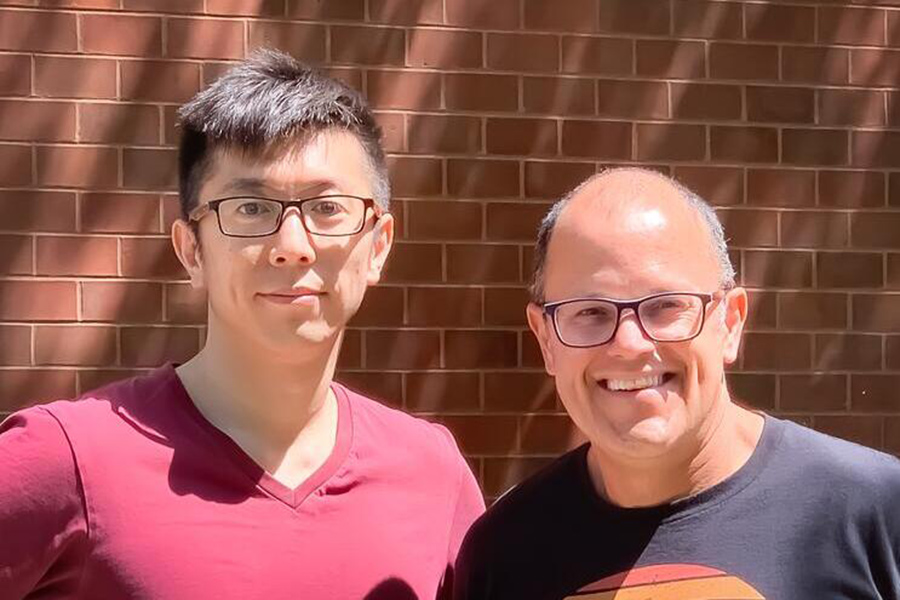

Jason Uen and Luis F Rodriguez conducted a systematic study of the feasibility of bioenergy production from food waste at the University of Illinois Urbana-Champaign. Credit: Marianne Stein

In a similar vein, US researchers have shown the potential profitability of generating energy from food waste.

‘We have a large amount of organic waste in the US, which can be converted into renewable energy using anaerobic digestion,’ says Jason Uen, a researcher at the University of Illinois Urbana-Champaign. ‘This deals with excess food and contributes to sustainable energy production.’

The researchers carried out a comprehensive analysis of supply chain logistics to determine if a system of converting food waste into energy and other bioproducts would be profitable in Illinois (J. Cleaner Production, DOI: 10.1016/j.jclepro.2023.137251). They used geospatial data to identify potential sites, then analysed technological and economic factors such as transport, production, revenue and return on investment. They found that installing anaerobic co-digesters at wastewater treatment plants – which had a total annual treatment capacity of 9.3m t – could generate an 8.3% return on investment and cut carbon dioxide by around 1m t/year.

‘There is still a big gap between the market demand for bioproducts and the amount of food waste we have,’ says Uen. ‘If we can expand the marketability of those products, the profitability for converting food waste into sustainable resources will increase.’

Seed funding

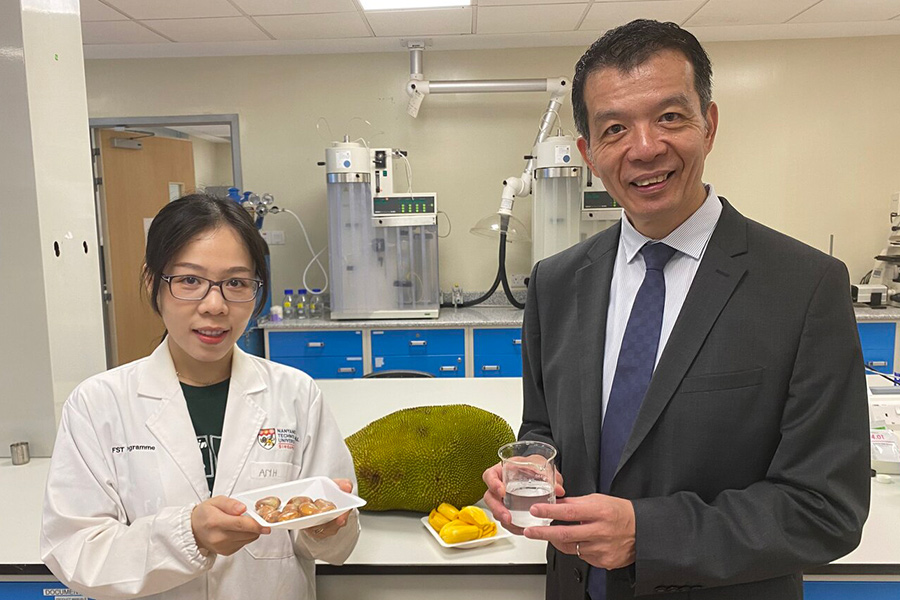

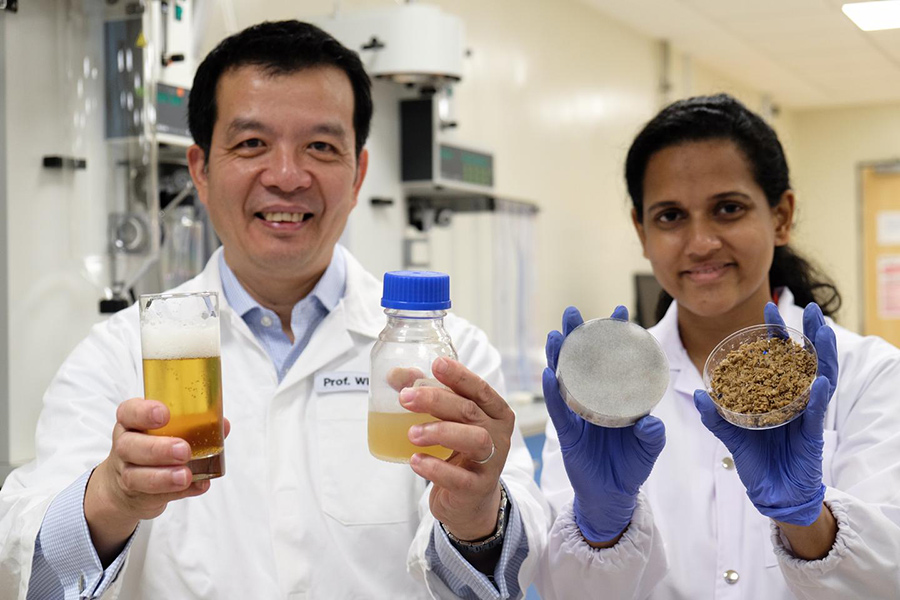

Tram Anh Ngoc Le, a PhD student from the Food Science and Technology (FST) programme at NTU, and NTU Professor William Chen, presenting jackfruit seeds and the lactic acid produced from the seeds. Credit: NTU SIngapore

Scientists in Singapore, for example, have identified how jackfruit seeds, brewing waste and kale leaves could be used to make valuable products including lactic acid, antioxidants and phytochemicals. Lactic acid is commonly used in the food industry to control acidity in jams or extend the shelf life of packaged meat.

It is usually made by fermenting raw materials like sugarcane, which is costly. Now, Nanyang Technological University (NTU) researchers have devised a way to make lactic acid from jackfruit seeds, which constitute around 20% of the fruit’s weight and are usually landfilled.

‘Upcycling waste jackfruit seed to make lactic acid is an opportunity to address the problems of rising production costs and waste management,’ says William Chen, director of NTU’s food science and technology (FST) programme.

Chen says the NTU method is cheaper and more sustainable than existing industrial methods. The seeds are washed, sodium hydroxide is added at room temperature, then the seeds are freeze-dried and blended to a powder.

A ‘good’ bacterium, Lactobacillus plantarum, is then added, which breaks the powder down into sugars and lactic acid (J. Functional Foods, DOI: 10.1016/j.jff.2023.105535). Chen’s team also managed to extract useful proteins from brewers’ spent grain (BSG) – responsible for around 85% of the waste from brewing beer. While some BSG is used for applications such as animal feed, a large portion still ends up in landfill.

Chen and PhD student Sachindra Cooray developed a new process to turn spent beer grains into a valuable liquid used to grow yeast. From right-to-left are are the brewer's spent beer grains, the fermented spent beer grains, which are made into a fermented liquid used to grow yeast, and beer. Credit: NTU Singapore

The researchers sterilised the BSG, then used Rhizopus oligosporus – a food-grade fungus – to break down its complex structure, making the protein content more easily extractable. The extract was dried, ground into a powder, sieved, and spun to separate the protein – with a yield of 200g of protein per kg of BSG. Once extracted, it could be added to foods to boost their protein content or combined with lotions or creams to boost their moisturising and antioxidant properties (Innovative Food Science and Emerging Technologies, DOI: 10.1016/j.ifset.2023.103551).

Kale extraction

Other NTU researchers have found a way to extract phytochemicals such as polyphenols from the outer leaves of kale plants, which are routinely removed before being sold.

Existing ways to extract these chemicals from kale require high pressure and temperatures – and can only target a single type of phytochemical each time. Now, researchers are using natural deep eutectic solvents (NADES) – non-toxic liquids made from plant-based compounds such as amino acids and sugars – for the extraction.

They found that, when kale waste and a NADES mixture is stirred and set aside, it naturally separates into layers, allowing easy extraction of the phytochemicals such as polyphenols, carotenoids and chlorophylls without the need for heating (Separation and Purification Technology; DOI: 10.1016/j.seppur.2023.123677).

‘Our method preserves the potency of the extracted active ingredients, making it highly attractive for industry adoption,’ says Hu Xiao of the school of materials science and engineering (MSE) at NTU. ‘The nutrients can potentially be used for applications in personal care, cosmetics, food supplements and herbal extracts.’

Aside from the ethical dilemma of wasting food, any foodstuff – including inedible peelings – will rot and generate methane if thrown into landfill. Until this can be solved, there is a chance to rescue the situation slightly by extracting value from an essentially worthless feedstock.